Last Updated on 17th April 2023

One scanner, many solutions

How one of the largest mines in the UK has adopted SLAM technology

ICL | A company with a rich history

With a history dating back to the 1950s, ICL are a global mining company primarily working in three markets; agriculture, food and engineered materials. Originally part of the establishment of Israel’s potash industry, ICL have over 80 years of intensive activity and major investment in R&D, making them a world leader in speciality fertilizers, bromine and flame retardants.

Located in the North Yorkshire Moors, ICL Boubly mine is the deepest in the UK and the world’s only polyhalite production facility. Polyhalite is a new, organic fertilizer produced and sold exclusively by ICL Fertilizers under the brand name Polysulphate. Field trials have proven that it is an effective crop fertilizer. It is found over 1,200m below the Earth’s surface, under the North Sea along England’s north-eastern coast. The incredibly effective ore comes from the polyhalite layer of rock, deposited 260 million years ago.

Boulby Mine | Early adopters of SLAM technology

Boulby mine was one of the first in the world to use SLAM technology, having adopted GeoSLAM’s ZEB1 into their workflow, in 2013. Nowadays, the mine operates GeoSLAM ZEB Horizons for most of their survey needs.

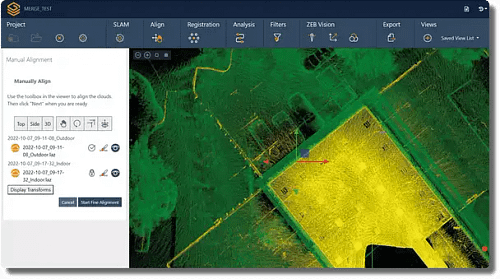

The small team of surveyors feel that the ZEB Horizon helps them achieve their survey targets. They work extremely efficiently, creating all the mine maps, calculating monthly production volumes and weekly surface stockpile volumes. The site have multiple stockpiles around the region to store their produce and the survey team are responsible for updating the companies accounts for stockpile volumes. Using the ZEB Horizon along with the automated GeoSLAM Volumes package, the survey team can scan these multiple stockpiles in a short time window, accurately and safely.

Taking full advantage of the ZEB Horizons versatility, the team not only use the walk-and-scan method, but also implement the UAV capabilities, capturing scans of stockpiles from the sky – a tool to suit all needs. Combining GeoSLAM’s hardware and software, the team at the mine can cover multiple sites, and are a valuable asset to the ICL group.

Scanning Stockpiles | The need for speed

The need for speed is critical when carrying out a stockpile inventory. Similarly, to ordinary stock audits, a count is done at a set time. At this time, the accounting team collect the “theoretical” stock, and then a physical count is done to correlate results (hopefully to have similar results). The same principle is applied to a stockpile, a time frame is given to measure its true volume, and this is compared to what the theoretical quantity is. For this, the following is needed:

A fast, reliable, easy to use system for capturing the stockpile

A software capable of processing the dataset in less than an hour

An automated process for removing infrastructure (loaders, conveyors and roofs)

A project level workflow, that will automatically calculate the volumes

The ZEB family, along with GeoSLAM’s new processing platform GeoSLAM Connect delivers data to be automatically processed on a daily/weekly/monthly schedule. GeoSLAM recognised there was a need to automate these repeated surveys, as well as ensure accurate surveys are carried out.

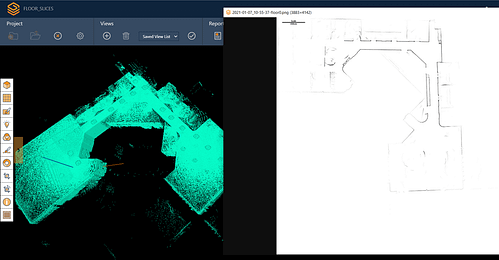

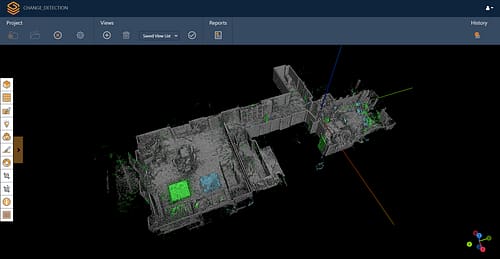

Scanning Underground | Keeping a mine on track

As well as stockpile surveys, the survey team are also responsible for doing multiple measurements at the mine. The ZEB Horizon is in a different class for productivity when scanning underground. The ease of use, rapid data collection and the amount of headings the system can scan in the small window the survey team have simply makes the ZEB Horizon the best tool for the job. Using the Adjust to Control feature of the ZEB range, the scans are also fully georeferenced, and can simply be dropped into the mine plan.

“We can catch the early lift down to the the mine, scan all the active headings (6-10 areas) and catch the lift back up to the surface before the mining team get going. Its important to measure these areas before the mining team are ready to go, the areas have to be safe for scanning and the survey team cant afford to hold up the mining team”

ICL Boulby

The mining team are given a target for the amount of tonnage they should hit per month and the survey team are responsible for measuring this and have to make sure the tonnages are being excavated along the right plane. The mine uses a variant of the “room and pillar” method. Its important to ensure the mining team do not excavate too much of the pillars as this could compromise the stability of the area.

To get in contact, submit your details in the form below and we’ll be in touch shortly.