Last Updated on 17th April 2023

The motivation and drive to create efficient and safe working environments for the mining sector across the globe is high. Emerging and rapidly improving technologies are helping to achieve these ambitions without hindering daily mining productions.

Using LiDAR and SLAM in the Mining sector

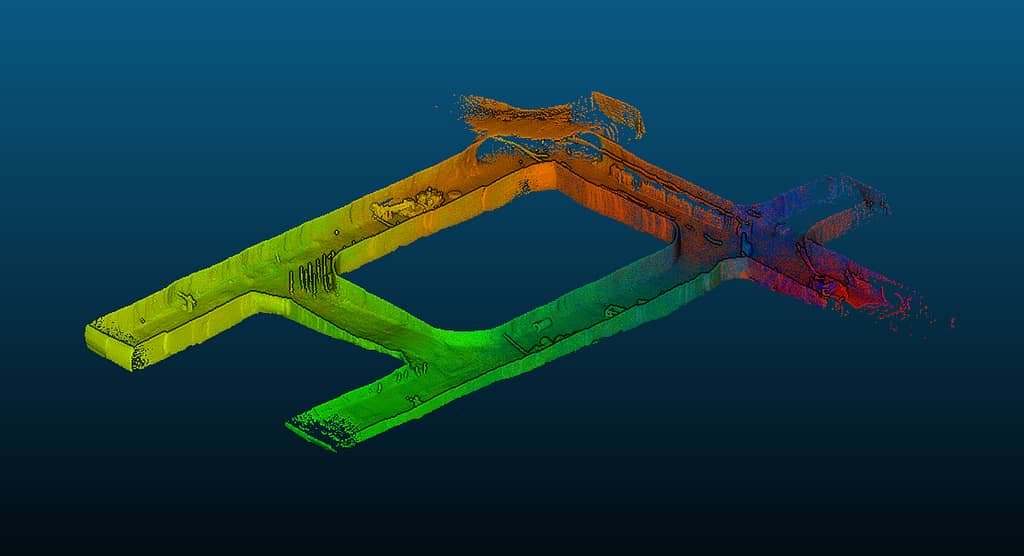

Mobile mapping using Light Detection and Ranging (LiDAR) is one example of technology that is already making mine surveying faster, more productive, and safer. The simplicity and versatility of 3D mobile scanners are proving to be impactful across a variety of mining workflows.

Traditional methods for data capture produce significantly high levels of detail. However, mobile laser scanners are handheld and more efficient at capturing point cloud data in short time periods, whilst still producing high levels of accuracy. This also reduces disruption to the daily workings of the mine and does not impact productivity.

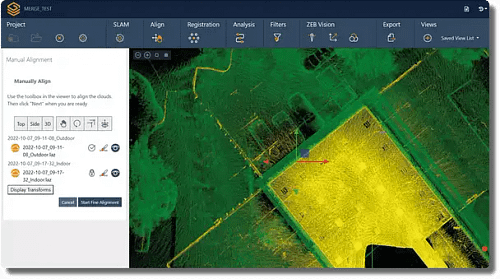

Mobile mapping using SLAM (Simultaneous Localisation and Mapping) algorithms is still a relatively new technology. Mines that are early adopters of SLAM have seen the benefits and adaptability of the scanners and have realised that they are an extremely cost-effective solution.

The capabilities of handheld laser scanners have large benefits for mines and their workflows. For example, GeoSLAM’s ZEB scanners make 3D mobile mapping a repeatable process due to their ease of use and speed of capture.

GeoSLAM technology is now being used globally as the sector recognises the improvements that a mobile mapping SLAM system brings to standard sector processes. Some additional processes that are taking advantage of this technology to reduce costs and downtime whilst improving site safety, efficiency, and automation are:

Production Progress Mapping

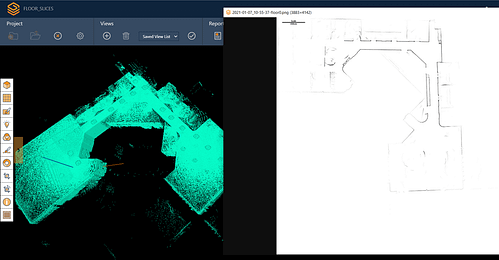

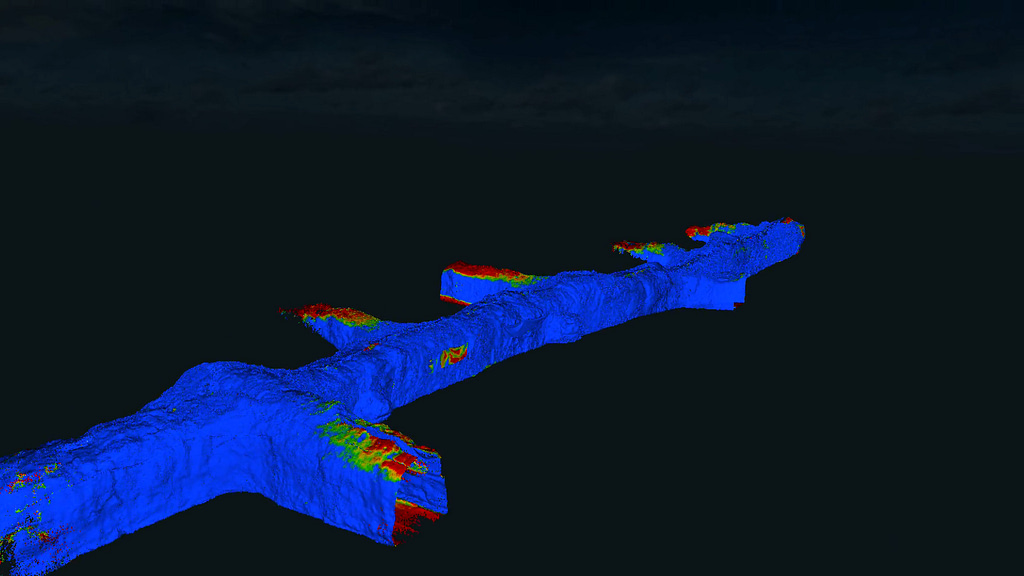

Tracking the progress of mining is essential to ensure that work is staying on course and that no deviation to plan is occurring. As a result, being able to frequently make effective short term operational decisions is vital.

With handheld LiDAR, scans can be easily repeated and analysed as often as needed, all whilst not disrupting the productivity of the mine. The ability to continually scan an area in short amounts of time allows teams to provide up-to-date maps of progress to compare to plan.

Convergence Analysis

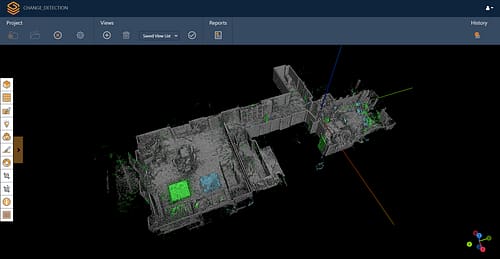

Detecting the velocity of rock movement is a critical indicator of potential slope/rockface instability. Therefore, accurately identifying convergence is paramount to ensuring the safety of employees. Handheld mobile mapping is a quick and repeatable process, allowing for more frequent data capture, which is advantageous within the mining sector.

With a greater amount of data available, due to the easier and more frequent scanning availability, convergence analysis decisions can be made faster. This saves both time and money, whilst also increasing safety.

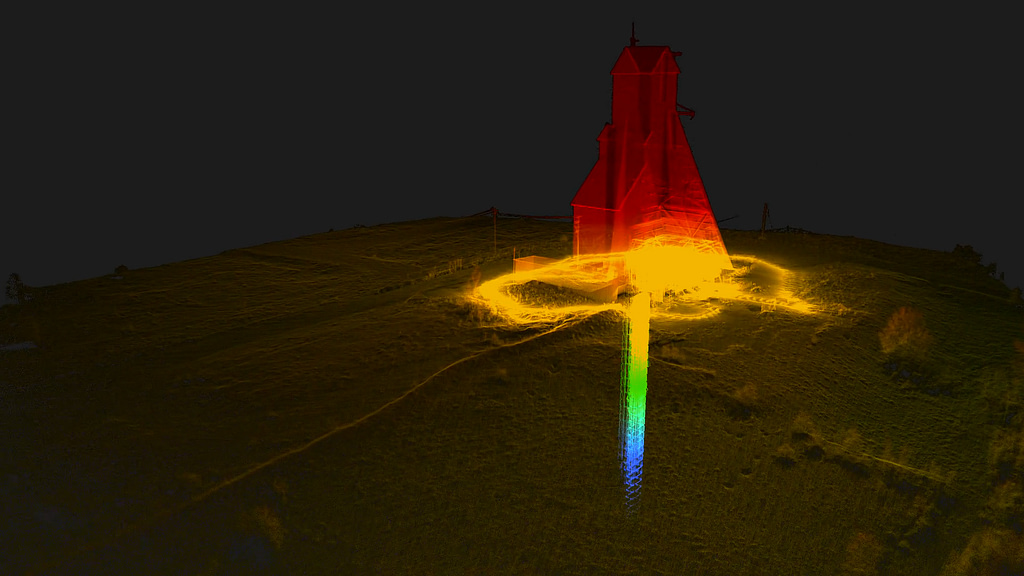

Vertical Shaft Inspection

Surveying and inspecting main ventilation, ore passes, or vertical shafts is important for ensuring the quick capture of shaft walls, without putting the workers in any form of danger. In addition, the ZEB Cradle or ZEB Guard are ideal accessories for assessing vertical shafts. It provides increased protection for the ZEB laser scanners and guards them against damage when being lowered into mines.

Stockpile Volume Calculations

As well as frequent underground use, handheld laser scanners are also used for regular data capture of stockpiles, for volume and tonnage calculations. Walking and scanning or attaching the mobile scanner to a UAV or pole provides an option for mine surveyors to determine accurate stockpile volume and tonnage measurements.

GeoSLAM’s Volumes software streamlines this process as it is specifically designed for usage in a variety of indoor and outdoor stockpile management environments.

The future of LiDAR and SLAM within the mining sector

The impacts that LiDAR and SLAM have on the mining sector are vast, from increasing processes and advancing workflows to ensuring the safety of workers. Using handheld laser scanners has benefitted mining as scans can be repeated frequently in short amounts of time, without disrupting productivity. The influence that handheld mobile mapping, with LiDAR and SLAM, has for the mining industry is only expected to grow. Therefore, companies would benefit from adopting these technologies to avoid falling behind.