Bloom Cloud Engine is a powerful on-premise point cloud editor ideal for use in Design, Fabrication, and Construction applications. Easy to deploy across your project team, BloomCE allows users to optimize and condition the point cloud data from all reality capture modalities, providing the fundamentals for Asset Management and Digital Twin project requirements.

Key Features include:

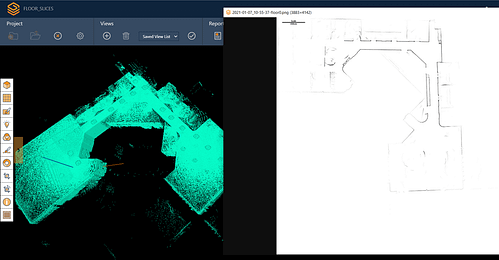

Point Cloud Editing

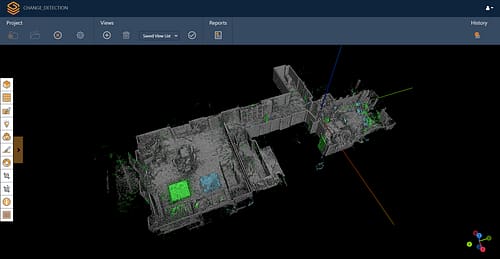

Analysis Tools – Deviation, Floor Flatness, Load Path, Progress Planning

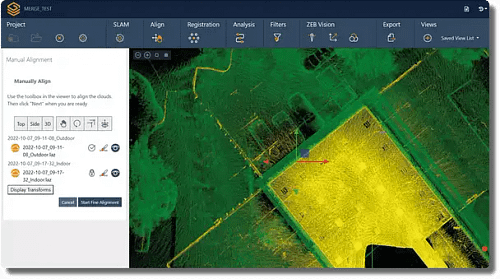

Transformation – Survey Control, Cloud-to-Cloud Alignment

Collaborative Viewing and Visualization

CAD Integration – Autodesk AutoCAD and Revit-based applications

Data Publishing – Bloom Explorer

For more information on Bloom Technologies contact the US Distributor point3D at [email protected]