How Using Micro Hydro Power Generation Produces Clean Energy

Discussions around climate change, and how we can lessen our environmental impact, have become increasingly more relevant in recent years. This has driven some companies and communities to explore different ways of producing renewable technologies, to reduce dependency on fossil fuels. One method for gathering renewable energy is by using Micro Hydro power generation.

Hydroelectric power generation relies on a constant water cycle. Nature is perpetually replenishing this, making it a good clean source of energy. This method of producing electricity using hydroelectric power generation is what the Congleton Hydro Project has set out to achieve.

Dane Valley Community Energy Ltd (DVCE), a non-profit community benefit society, developed and constructed the project. DVCE is a volunteer led organisation, run by a small team of volunteer directors, who have all worked within Engineering and Management Companies. Funded by the community of Congleton, the project aims to generate enough carbon-free electricity, using hydroelectric power generation, to power 60 homes within this local area.

Utilising an Archimedean Screw for Micro Hydro Power Generation

For this project, the team set up a Micro-Hydro System, including an Archimedean Screw. The hydroelectric energy is generated by the nearby Havannah Weir River. The energy is extracted by using the water flow to turn the Archimedean Screw, which is connected to an electrical generator. Having constructed the whole system in just 12 months, DVCE were able to produce their first load of electricity in a relatively short space of time.

The area surrounding the Archimedean Screw required significant and extensive ground works, together with a substantial walkway, powerhouse, and piped water inlet system. Whilst designing the project, it became apparent that a core worry would be movement of the terrain, due to weather and time. As a result, they decided they needed to frequently monitor this surrounding area.

The Archimedean Screw has a life expectancy of 40 years, and the team hope to make returns on their investments in the next 20 years. In addition to generating clean energy, a core objective is to generate an annual surplus, which will fund the local community. It is therefore essential that any change in land stability does not impact the planned generation. The team decided that a monitoring system would help identify any movement so that timely corrective action could be taken.

Tracking Changes in the Land and Facilities Management

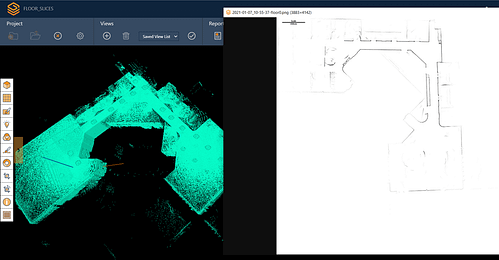

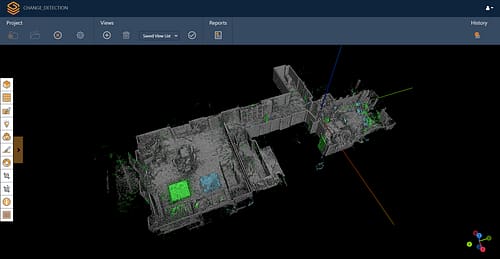

Via a family member (Dr Jonathan Owen), the team acquired a 3D handheld laser scanner, GeoSLAM’s ZEB Go. The handheld nature of the scanner will mean they can track land movement and vegetation rates over time. In addition, they can map the on-site building to help with facility management and storage.

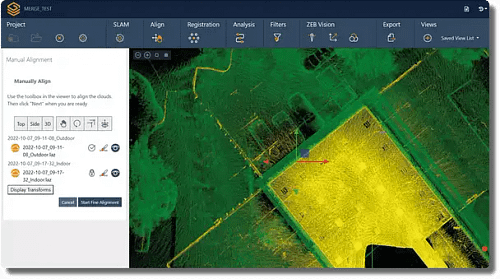

GeoSLAM Connect’s Stop and Go Alignment can help the team align these scans, as it would give them a more accurate view of the exterior and interior areas together.

GeoSLAM technology is ideal for this type of work, due to the uneven terrain. The mobile device can map an area by simply walking around, whereas systems that require a more complicated setup would struggle to scan the area promptly.

The Benefits of GeoSLAMs Technology

The ZEB Go’s speed of capture enables DVCE to carry out scans of the 100m x 100m area surrounding the Micro-Hydro System in just 25 minutes. As the team are detecting change in the ground movements and vegetation, they can frequently scan the area to track any issues that may arise. A great way to document the area, as frequently as DVCE need.

The ZEB Go’s ease of use means the team would not need to be survey trained for the scan, unlike more complicated to use scanning hardware. Further, the ZEB Go’s capabilities save all the team from having to repeatedly return to the site, as just one individual is needed.

The team were impressed with the ease that the ZEB Go was used to survey the complete site, with no tripods being needed and no complicated set up.

Creating Accurate Georeferenced Point Clouds

Whilst capturing the data, the team laid down control points using a GNSS receiver. This allowed the team to georeference the data using GeoSLAM’s software. Now the surveying pins are in place, the team can simply georeference the data for each scan they conduct.

Implementing control points was important for DVCE as it allows for clear comparisons between multiple scans of the same area. Georeferenced data places the scan in the real world and makes the data even more accurate. This will benefit the team as they continue to scan the Micro-Hydro System’s surrounding areas in the future and detect any gradual change.

The ZEB Go delivered an accurate 3D replica of the area that continues to help DVCE in their project. The versatility of the ZEB Go and resulting point cloud means the team can look into new ways to interpret the data – protecting this vital equipment for both the environment and local community.

Jonathon was the lucky winner of our ‘Win a ZEB Go Competition’ at GeoBusiness 2021.

Get in touch

If you’d like to learn more about how GeoSLAM solutions can help you, submit the form below.