Laserscanning Europe | German Dealer

GeoSLAMs German dealer, Laserscanning Europe, were recently tasked with scanning a 70m deep cavity in a mine 500m below the earths surface. Using the ZEB Horizon on a cradle, Laserscanning Europe were able to successfully and safely capture the data, and this is their account of the job.

Data captured by Laserscanning Europe

Scanning with the ZEB Horizon | Words by Laserscanning Europe

The object of measurement is located in the Hattorf/Wintershall mining facility of the company K+S Minerals and Agriculture GmbH. This is a cavity (underground, vertical conveyor system) about 500m below the earth’s surface with a depth of 70m.

The cavity no longer has the original storage volume due to material deposits from years of operation. The environment is dusty and it is expected that material will be deposited within the conveyor system at any time. In addition, the cavity is not accessible to humans from any opening and access is only possible through 1m diameter openings.

The objective was to obtain a three-dimensional survey of the conveyor system with highest possible resolution for inspection of the systems condition. Furthermore, strict compliance with all work safety regulations, with minimal risk for the measuring team, was required.

For this job, a mobile laser scanner was used. Thanks to its specifications, the GeoSLAM ZEB Horizon is ideally suited for the special conditions underground. The scanner is also suitable for surveying a cavity that is only accessible from above through a narrow shaft.

The scanner was mounted on a cradle, which was modified to minimise rotational movements when lowered. A 50m rope was attached to the cradle, which was used to lower the measurement system into the cavity.

Furthermore, trained members of the mine rescue team were on site to provide security and enable the scanner to be lowered and retrieved safely.

Workflow of the analysis

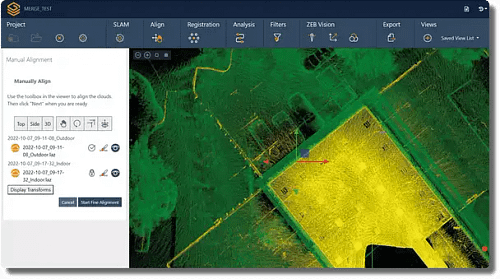

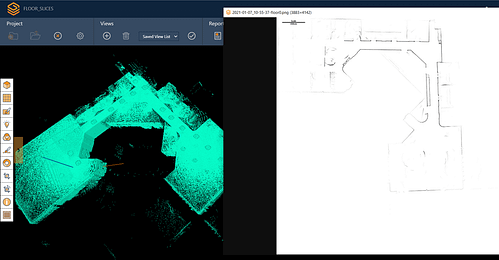

Following the survey, the scan data was processed using the GeoSLAM HUB software. The raw data, i.e. the processing of the point cloud from the data of the laser sensor and the IMU, is automated as much as possible. In the case that a scan was not automatically processed (e.g. because few geometric changes are found in the object space), the focus of the SLAM algorithm can be influenced by adjusting various parameters. Once the data has been run through GeoSLAM Hub, a complete point cloud of the cavity is available in .laz format. All other common point cloud formats can also be exported with little effort.

Since the scanner could only be lowered linearly on the rope, the earth deposits shadow smaller areas inside the cavity.

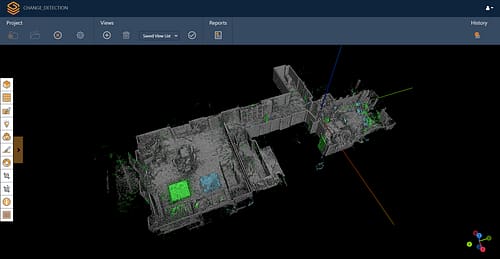

Results

The result of this scanning is impressive. This cavity, which is not accessible to humans, was successfully surveyed with the help of the GeoSLAM ZEB Horizon. The point cloud documents the dimensions of the cavity according to the requirements. Further missions with the GeoSLAM ZEB Horizon with similar objectives are already being planned and implemented.