Last Updated on 25th April 2022

When creating underground mapping for mines, mining engineers are often faced with having to work in hazardous and rugged environments, in difficult-to-access spaces and without GPS coverage. In order to address these challenges, mining companies are continuously searching for ways to plan efficient site operations, streamline tunnelling processes and optimise production and personnel safety.

Kidd Mine, an underground base metal mine in Canada and the world’s deepest copper/zinc mine, epitomises this by adopting new and advanced survey technology. With the aid of GeoSLAM’s 3D mapping technology, the mine is able to assess risk associated with ground and support systems failure, magnitude seismic events, large-scale deformation or rock bursts associated with mining at extreme depths.

Built for harsh and demanding environments, GeoSLAM’s handheld laser-scanners are robust, splash-proof and dust-tight (with ratings up to IP64 level). They’re adaptable to any environment – inside or outside, in daylight and darkness – without the need for GPS. Lightweight and easy-to-use, you can walk and survey accessible areas quickly and easily – even those which are normally off-limits. For more confined or unreachable places, they can be attached to trolleys or mine vehicles for remote monitoring.

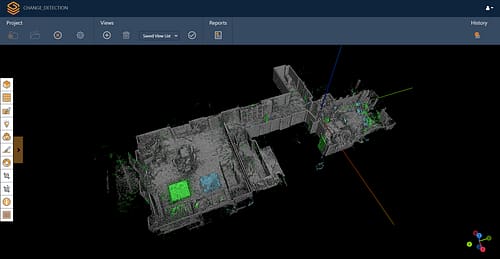

David Counter, a senior ground control engineer at the Kidd Mine, emphasised the importance of using a hand-held laser scanning device to map the underground areas at the mine. “It produces a continuous 3D animation image of whatever underground areas are being scanned as the user walks along the drift. This allows the mine to map out problem areas and to carry out ground support rehabilitation in those areas. The ZEB Revo provides a background dataset that can be used for comparative purposes if a future high-magnitude seismic event occurs or for determining how much static deformation has been occurring due to regional mine closure over time. It’s critical data that will help us lower the risk to personnel and keep mines safer.”

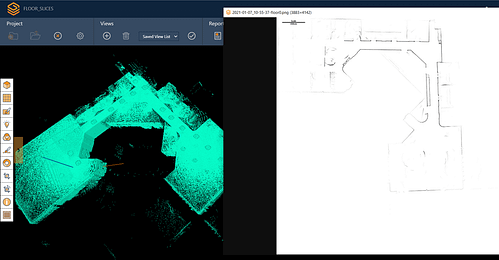

Despite needing to rapidly map mines under intense time constraints, traditional underground survey techniques have proved to be slow. Mine engineers and surveyors all need access to user-friendly technology that is easy to install and use, but is robust and reliable enough to do the job quickly and accurately. Within minutes anyone can be using a GeoSLAM scanner and immediately start creating a 3D point cloud of the area. Data is collected continuously while walking the survey area – with no time-consuming or cumbersome set-up required.

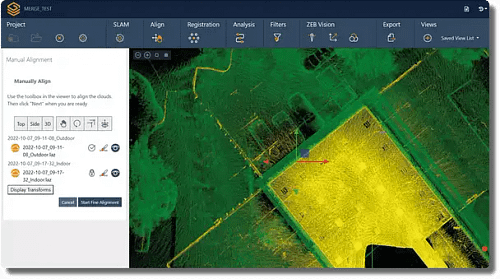

GeoSLAM’s award-winning software instantly turns data into actionable 3D information. So, you can rapidly gain insight into rock mass behaviour and map out deformations in rock walls & complex tunnel profiles. Plus, accelerated survey workflows help you deliver productivity and efficiency improvements, at the same time as helping you hit your zero-harm targets.

“There is a sound basis for SLAM laser technology to define areas where the ground support systems need to be replaced or rehabilitated,” Counter concluded.