Vertical Shaft Inspection Made Easy

Rapid, safe in-motion data collection in hard to reach areas and dangerous vertical shafts for inspection and monitoring. Use GeoSLAM shaft inspection technology for 3D visualisation or further analysis.

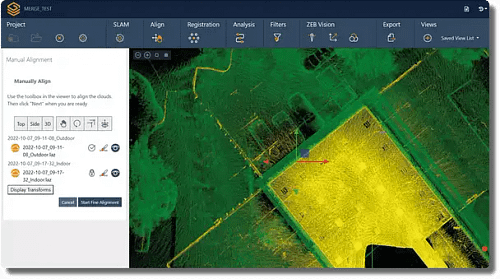

Adjust to Control

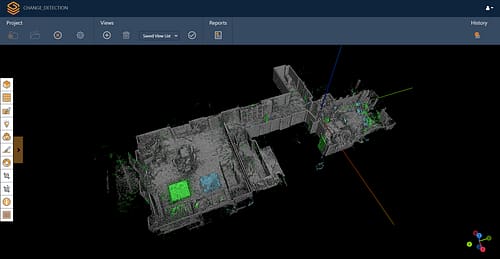

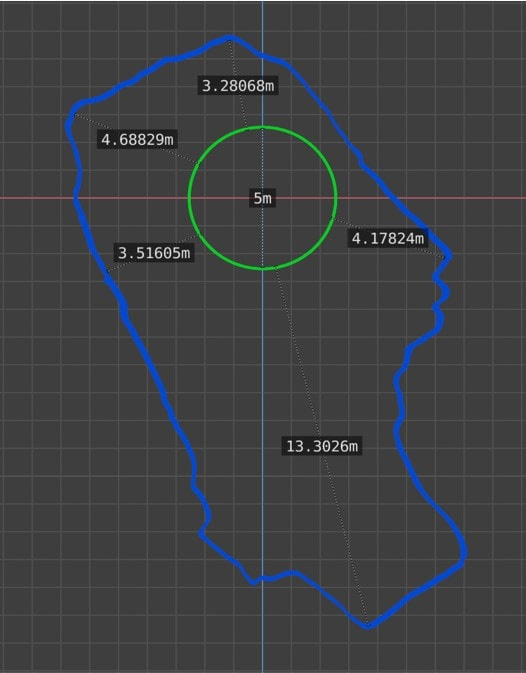

Adjust to control allows for the data to be georeferenced as part of the SLAM processing. This means all data exports will be in the right coordinates, and can be imported directly to the mine plan or for comparative analysis.

Third Party Software

GeoSLAM data is seamlessly used and integrated into 3rd party mine mapping software such as Micromine, Deswik and other leading software packages. This means you can process it using the systems you already have and are comfortable using.

How do you inspect a mine shaft?

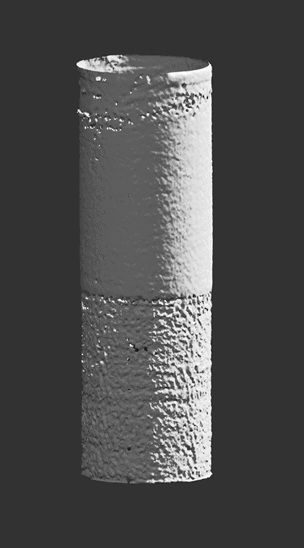

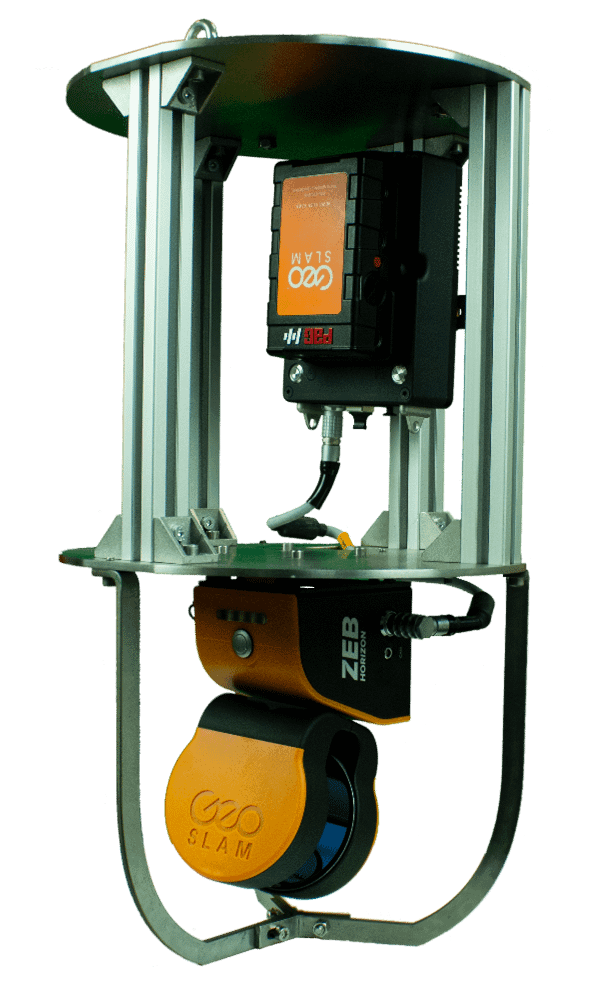

1. Capture

Using a purpose designed cradle, lower your ZEB to create a digital map of the full depth of a shaft or ore pass.

2. Process

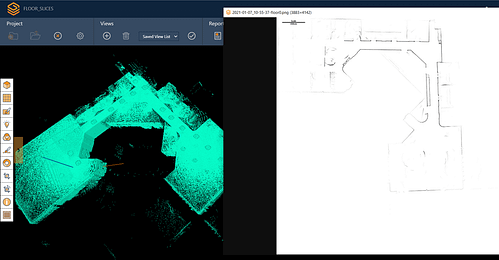

Transfer the data to a computer, and GeoSLAM’s smart data platform, Connect, will automatically process the data.

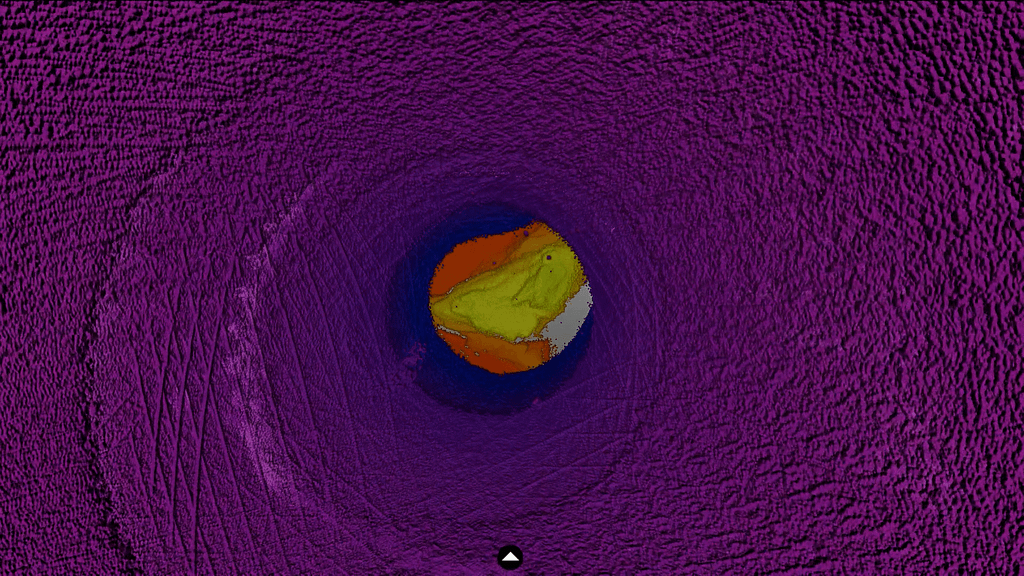

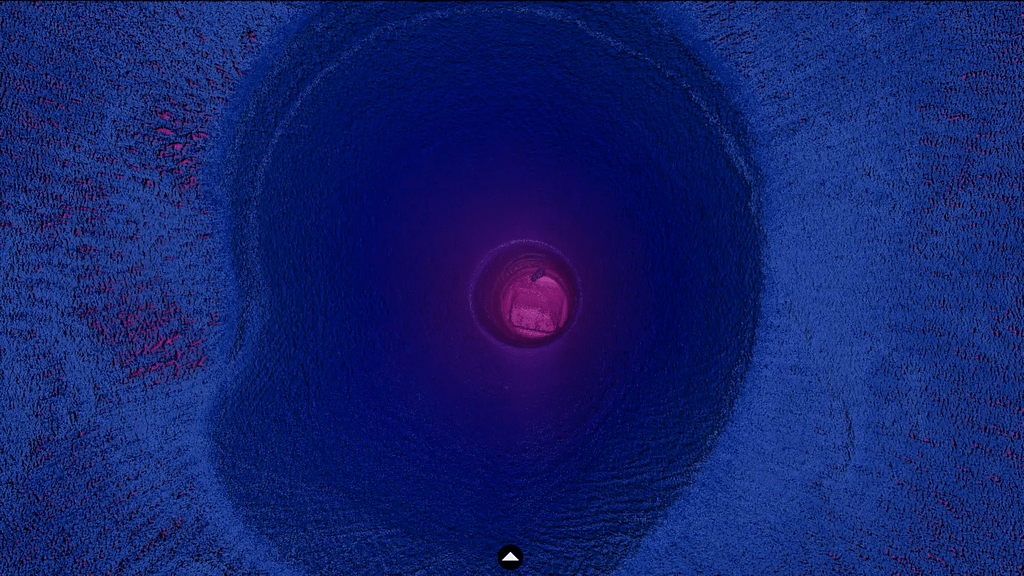

3. View

See, and quality control your processed digital 3D data in a few minutes. Choose your preferred output format and create a full or sub-sampled set to export.

4. Manage

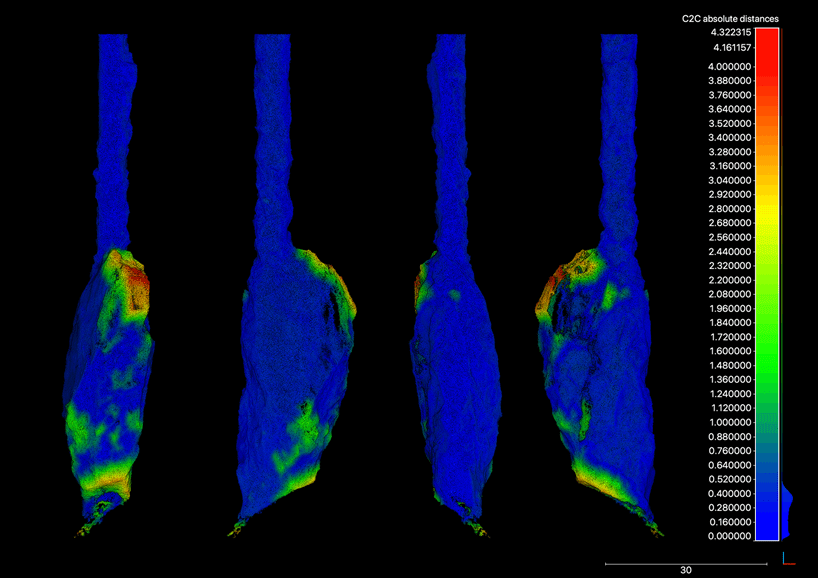

Use the exported data in any 3rd party system for further analysis by using cross sections, creating mesh or solids and comparing to a design.

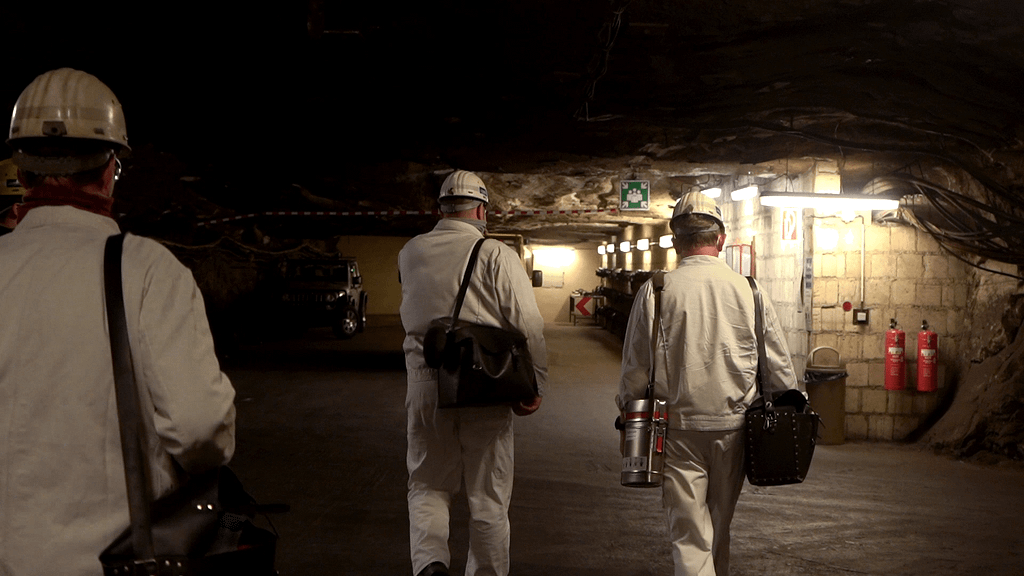

GeoSLAM for mining in action

See our 3D scanners being used to make mine shaft monitoring safer.

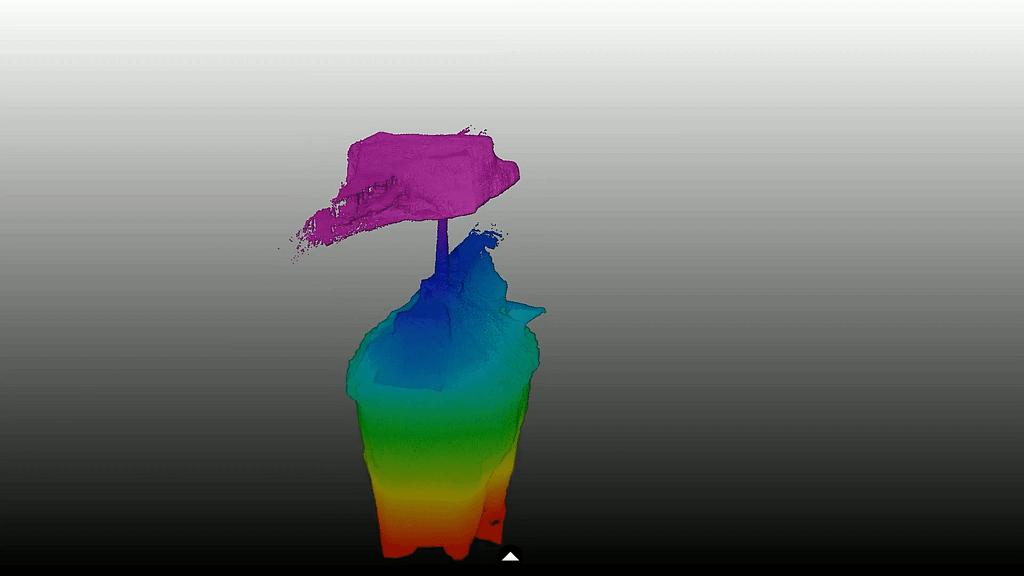

CASE STUDY: Scanning a cavity with the ZEB Horizon

GeoSLAMs German dealer, Laserscanning Europe, were recently tasked with scanning a 70m deep cavity in a mine 500m below the earths surface. Using the ZEB Horizon on a cradle, Laserscanning Europe were able to successfully and safely capture the data, and this is their account of the job.

Location: Hattorf, Germany

Industry: Mining

Scanned: Cavity

Rugged, easy to deploy shaft mapping for safe, productive underground mining.

Lower your ZEB device into vertical shafts using the purpose built cradle or ZEB Guard to understand the full size and shape of shafts or ore passes.

Which ZEB laser scanner is right for you?

ZEB Go

Used mostly for scanning indoors or in underground mines and caves with an IP64 rating. Can be used outdoors and has a range of 30m.

ZEB Horizon

The most flexible of the ZEB family with a range of accessories. Can be used to scan indoors and outdoors with a longer range of 100m.

Want to learn more about GeoSLAM and how it could transform your business?

News

Keep up to date with the latest news and thought leadership from GeoSLAM.

Why is Geospatial Information so Important?

Why is Geospatial Information so Important? Geospatial technology like LiDAR…

Underground 3D Mapping with handheld SLAM scanners

With the recent introduction and constant evolution of handheld SLAM…