SmartScan: Making Shotcrete Thickness Calculation Easy

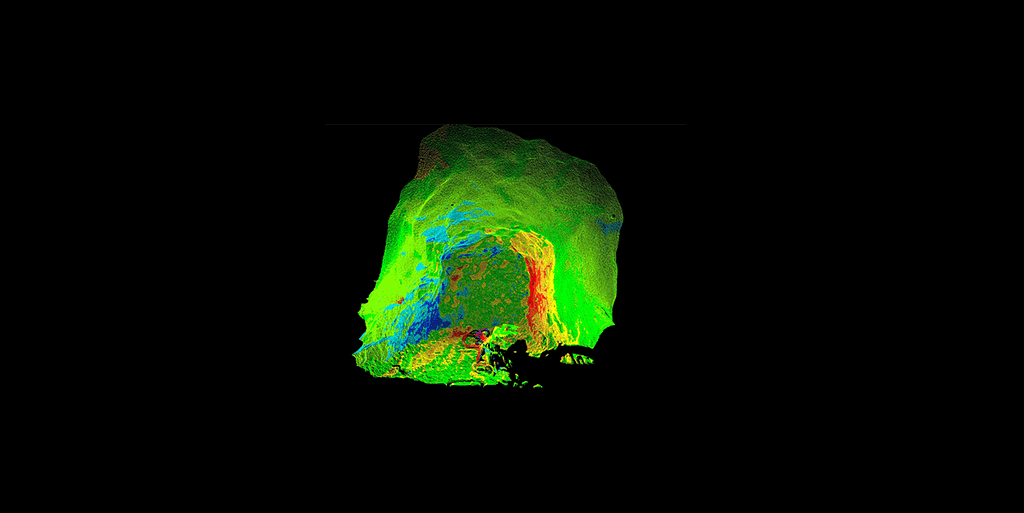

Sprayed concrete (or shotcrete spraying) can generate excessive waste: costing too much, or uneven application, compromising the safety of the tunnel, your equipment, and workers. The team at GeoSLAM have designed and built an intelligent shotcrete thickness analysis tool to help you ensure your sprayed concrete is applied to the correct thickness using LiDAR scanning.

The GeoSLAM shotcrete product is sold exclusively by Normet under the SmartScan name.

How can SmartScan improve Shotcrete Analysis?

Scanning Shotcrete in Mining

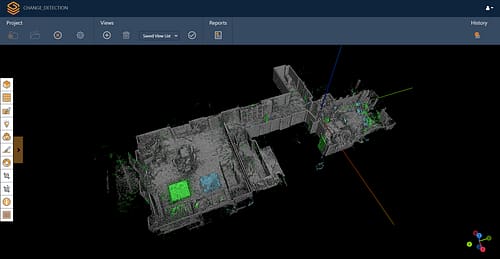

The Sika Sprayed Concrete Handbook states that the only method for accurately calculating initial strength is by measuring thickness. Current methods rely on operators endangering themselves to un-secured shotcrete in order to manually collect thickness readings. A total of 5% of all tunnelling injuries can be attributed to the shotcrete process in tunnelling. Industry professionals recognise the need to balance the provision of a safe working environment for its operators with the demand for increased production rates, accurately measured and documented shotcrete thickness.

Applications

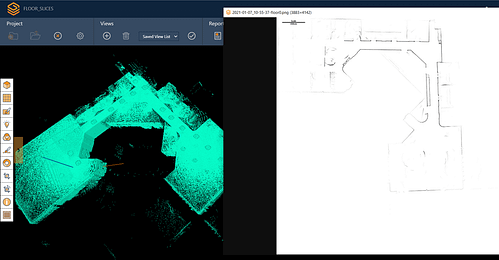

Sprayed Concrete Measurements

Underground Construction

Bridge and Structural Repairs

Tunnel Lining Maintenance

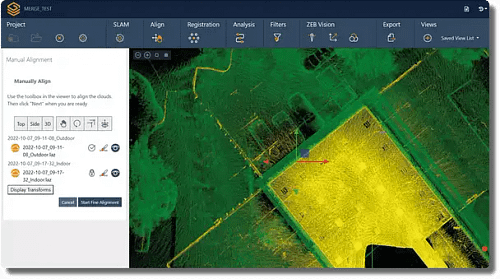

New technologies, such as laser scanners, are helping to improve the concrete spraying process for tunnel construction

Want to know how SmartScan can help you?

News

Keep up to date with the latest news and thought leadership from GeoSLAM.

New partnership for GeoSLAM and NORMET

GeoSLAM is pleased to announce a new partnership with the…

PROCESSMONITOR LIVE shotlisted for Tunnelling Award!

We’re pleased to announce that our solution for safer sprayed…

The benefits of measuring Shotcrete during application

Ground support operations are critical in most underground mines, not…