Last Updated on 25th April 2022

World population is growing faster than at any time in history, and as the global standard of living increases, so does the demand for metal and mineral consumption. This puts tremendous pressure on mining organisations not only to sustain their output but to find ways to further increase production and profitability in a highly competitive industry. However, digital technologies are enabling underground mines to make their operations more efficient and profitable through 3D mapping technology that enables mining operators to collect vast quantities of accurate data about their operations remotely and in real-time through internet-connected sensors.

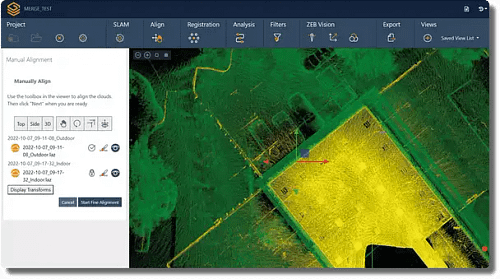

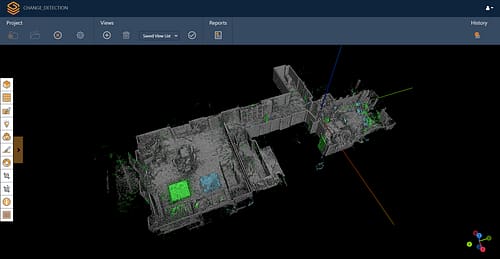

A typical example of this can be found at the Lingbao Gold Mine mine in Henan Province of China which utilises GeoSLAM’s 3D mapping technology to quickly and effectively capture locations of piping, drill holes, pads or shutes and other underground assets. With the aid of GeoSLAM’s handheld laser-scanners, survey teams can work faster and with greater confidence knowing that accurate topographic and volumetric data is guiding mine planning and geographical investigations. Fast-built 3D models can be read directly which facilitate mine design and management.

Underground in Henan Province at a depth of 240m

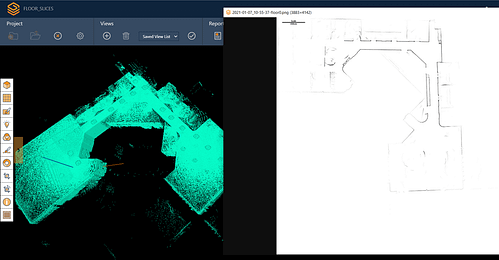

Designed for harsh underground environments GeoSLAM’s robust and light-weight laser-scanners make them ideally suitable for confined spaces, shafts, raises, ore passes or tunnels. The lack of artificial lighting is not a problem as they can be used night or day, and without the need for GPS coverage.

Unlike traditional survey methods that require time-consuming setting up of bulky equipment, and often unmanageable in very tight places, GeoSLAM’s user-friendly laser-scanners allows the operator to ‘walk and scan’ while simultaneously transmitting high-level fidelity images to the processing hub – and can be over 10 times faster at acquiring data. This data can then be acted upon and used to improve efficiency on-site, ensuring a safe environment for miners and monitor the operational status of machinery. GeoSLAM’s non-intrusive laser-scanners require little or no disruption in operations.

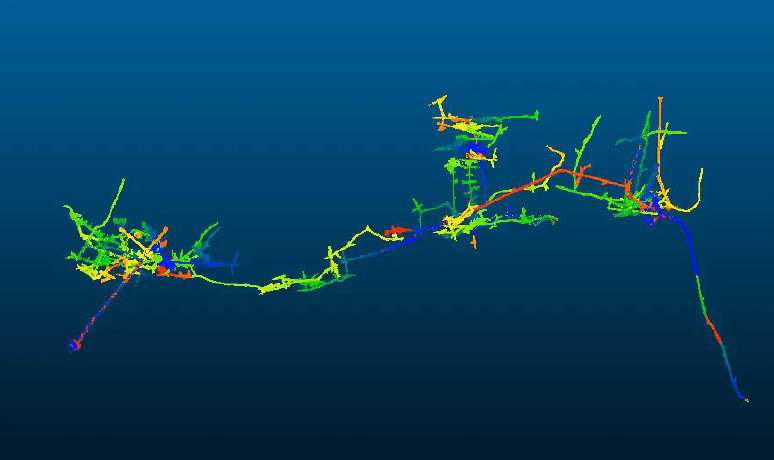

Zoomed out view of the mine complex

“With 3D spatial information, we are able to study more insight into resource models and identify residual resources. This is especially valuable for precious metal deposits as we can rapidly and confidently identify differences between designed and actually mined” said Dr. Sheng of Beijing SCR Instruments, GeoSLAM dealers in China. “Time restraints mean that survey teams will often have a very limited time on-site to accurately create actionable 3D models. GeoSLAM technology rises to this challenge by producing accurate data at a considerably less time than traditional survey techniques, which means that management decisions can be made faster and with greater confidence.”

In environments that are inaccessible, difficult to reach, or simply too hostile or extreme to safely deploy humans, a robotic solution is needed. GeoSLAM’s light-weight laser-scanners can be attached to a drone or mine vehicle for inspecting and mapping dangerous or otherwise difficult to access areas, or identifying any roof collapse hazards or rock falls. The challenge for mining engineers and surveyors is to balance gaining rapid insight into rock mass behaviour and complex tunnel profiles; at the same time as achieving zero-harm targets. GeoSLAM’s technology safely provides this bridge.

Find out more about using GeoSLAM in mining applications here.