Last Updated on 25th April 2022

Words by Guy Kantorowich, British Gypsum.

Background:

Stockpile surveys are the ‘bread and butter’ of many surveyors, with regular surveys required from an accounting standpoint. Depending on the material being surveyed, how accurate the survey needs to be, and how the stockpile has been constructed the survey can be quite laborious and time consuming. Also if the site, as in this case study, is an active quarry operation with moving machinery and plant the survey can pose certain health and safety risks to the surveyor, who has to negotiate climbing over and around the stockpile whilst also avoid collisions with any moving plant. Since the development of rover GPS units this was the preferred method for conducting such a survey. The surveyor can accurately map the stockpile with one instrument with little else required. Processing the survey is also a relatively simple task especially when you have the base of the stockpile surveyed to GPS as well. The drawback is that the surveyor has to physically take every measurement required to map the stockpile which, as previously mentioned, can be very time consuming.

GeoSLAM’s ZEB Horizon is a portable hand held laser scanner which offers a solution to some of the problems with the traditional GPS method. The scanner boasts impressive figures with 300,000 points per second collected, 100m range with up to 1cm accuracy all surveyed in real time whilst on the move. The ZEB Horizon produces point clouds in various export formats with the function of reducing the number of points in the survey by a percentage to reduce the file size and processing times. The unit relies on SLAM (Simultaneous localization and mapping) technology which is simultaneous localization and mapping is the computational problem of constructing or updating a map of an unknown environment while simultaneously keeping track of an agent’s location within it.

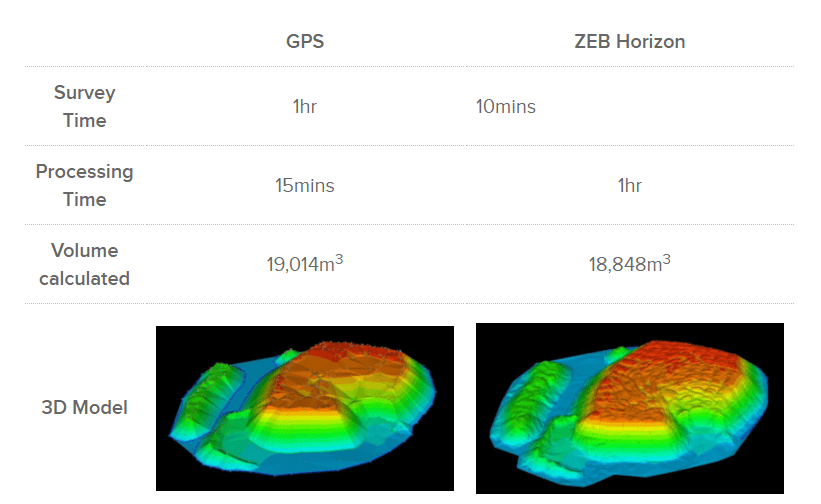

To assess the capabilities of the scanner compared to the GPS we conducted the monthly quarry stock survey with both instruments on the same morning.

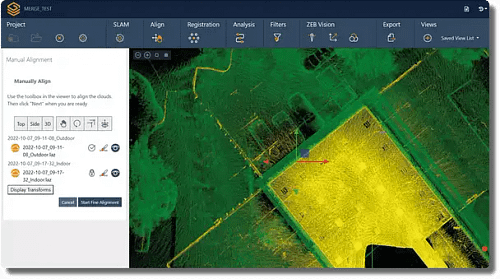

Geo-referencing Point cloud

Depending on the conditions of the stockpile a base survey of the stockpile area may be required. This is generally done when there is an uneven surface or obstructions beneath the stockpile which need to be taken into account when calculating the volume of the stock. For this case study using a GPS base model was important so geo-referencing the point cloud was required. We used three spheres placed around the stockpile, which were surveyed by placing the GPS receiver on top of the sphere and then reducing the level to the centre of the sphere. In post processing the coordinates were assigned to the spheres picked out from the point cloud to then accurately geo-reference the survey.

GPS Rover vs. ZEB Horizon

Conclusions

There is quite a stark difference between the two methods especially when you look at the time spent on site carrying out the survey. The longer processing time is a small price to pay when you can reduce your survey time significantly. The less time the surveyor spends on-site in a potentially hazardous area the better. There is a difference in the volume calculated, but at only 166m3 this is negligible especially when you look at the models and level of detail in each of the surveys. This difference is almost certainly due to the ZEB Horizon survey being more detailed and thus more accurate. A smaller sampling strategy adopted by the traditonal GPS method means most of the data needs to be interpolated, the Zeb Horizon allows for a more even sampling rate to better represent the whole stockpile rather than assume data.

The ZEB Horizon also has the potential to be vehicle or UAV mounted. This would further reduce the risk to the surveyor. Internal stockpiles are surveyed with even greater ease when compared to a one-man total station with no more multiple set-ups and complex resections.

Overall I believe that this technology has the capabilities to completely revolutionise the surveying of stockpiles. As a surveyor who has spent many years clambering over stockpiles getting increasingly frustrated at the complex, uneven, messy nature of them the ZEB Horizon is a breath of fresh air.