What are the benefits of LiDAR in Civil Engineering?

Last Updated on 21st December 2022 What are the benefits of LiDAR… Read More »What are the benefits of LiDAR in Civil Engineering?

Last Updated on 21st December 2022 What are the benefits of LiDAR… Read More »What are the benefits of LiDAR in Civil Engineering?

Location: Norway

ZEB Scanner: ZEB Horizon

Scan time: 15 Minutes

Would you like to see a specific dataset that’s not on this page? Contact [email protected]

Last Updated on 7th October 2022 The benefits of BIM and Scan… Read More »The benefits of BIM and Scan to BIM

Location: Europe

ZEB Scanner: ZEB Horizon/ ZEB Discovery

Scan time: 15 Minutes

Colourised data was captured using the ZEB Discovery backpack solution.

Would you like to see a specific dataset that’s not on this page? Contact [email protected]

Control points are points within a given area that have known coordinates. They are a key tool in the geospatial industry and can be utilised in a variety of ways, including georeferencing point clouds and aligning aerial images to terrestrial data. By using control points, surveyors are able to accurately map larger areas and position overlapping surveys of an area together. They can also be used in non-geospatial industries, such as construction and mining, to show clear temporal comparisons between multiple surveys of the same area. This method of georeferencing is also referred to as adjust to control.

Previously, checkerboards and spherical targets have been used as control markers – these items are captured in surveys and can be identified for georeferencing or aligning. The main drawback with these methods is that they rely heavily on human interpretation when processing, meaning that the processed datasets may be susceptible to an increased amount of error.

When capturing handheld surveys, GeoSLAM systems are able to collect reference points. These can then be matched with known control points to reference scans and increase the level of accuracy.

Easily reference point clouds and produce reports highlighting accuracy values.

Regularly monitor site operations (e.g. stockpiles) and hazards.

Compare changes over time and map progress onto predetermined CAD/BIM models.

Once georeferenced using control points, point clouds can be optimised further using leading third party software:

For more information about our third party partnerships, head to our integrations page.

Keep up to date with the latest news and thought leadership from GeoSLAM.

With increasing awareness of LiDAR technology, its applications are becoming more diverse….

Popular Nottingham bar as you’ve never seen it before A historic chapel,…

Using 3D laser scanning to map difficult environments The advances in handheld…

Location: United Kingdom

ZEB Scanner: ZEB Horizon

Scan time: 45 Minutes

Would you like to see a specific dataset that’s not on this page? Contact [email protected]

Industry

AEC

Time

100 hours

Location

Singapore

Size

376 ground

floor void

decks

Scanned

Apartment

blocks

Singapore is home to some of the most profitable financial services, manufacturing and oil-refining corporations in the world. But with its accomplishments come some very specific challenges for a city-state which is limited by space but still demanding growth.

Determined to future-proof Singapore’s success, the country has embarked on one of the most ambitious digital twinning projects the world has ever seen – creating a dynamic 3D city model and collaborative data platform, including 3D maps of the region.

At the initial stage of the project it quickly became apparent that aerial imagery alone would not be able to capture ‘void decks’ – open spaces typically found on the ground floor of the city’s apartment blocks. These areas, which are sometimes underneath the tower block structure, are used for everything from games areas, bicycle parking, hosting wedding receptions and wakes, and, as estates grow, facilities such as shops, medical centres and even schools.

In the face of fierce competition, GeoSLAM’s ZEB Revo was selected as the most innovative and efficient solution to collect data from these important community spaces.

“A huge time saving exercise which would ordinarily have taken 40 times longer using traditional surveying methods“

With a handheld “go-anywhere” ZEB Revo, field teams quickly captured a dense and accurate point cloud of an entire void deck, which was then used to model the deck geometry and incorporate this into the existing building models.

376 buildings with void decks were scanned using the ZEB Revo, taking approximately 100 hours – an enormous time-saving exercise which would ordinarily have taken up to 40 times longer using traditional surveying methods.

The ZEB Revo is often used alongside terrestrial hardware as the products are highly complementary. The data output can be easily combined through geo-referencing or scan-to-scan matching and then used to build complete 3D models. In this instance, the combination delivered highly detailed and rapid results while significantly minimising costs too.

Industry

Civil

Engineering

Location

Minnesota,

USA

Size

4,500

manholes

Scanned

Sewer pipe

network

Public works and energy utilities are continually looking for new ways to protect the safety of their personnel in the field. With the help of the GeoSLAM ZEB Revo mobile laser scanner and the specially designed GeoSLAM Cradle, the cramped and hazardous spaces in manholes can now be captured in 3D without putting field workers at risk.

“An engineering survey firm scanned the interiors of 4,500 manholes with the ZEB Revo for a Minnesota municipality,”

What lies beneath the manhole covers found in nearly every city and town varies considerably. Some are access points to extensive storm water and sewer pipe networks. Others are entries into utility conduits through which water mains and electric lines are run. A few manholes are simply tight underground spaces where key pieces of municipal infrastructure reside.

Regardless of their function, manholes and the assets they contain are difficult and sometimes hazardous to map. Not only are the interior spaces dark, dirty, confined and usually wet, they pose potential risks related to cave-ins, poor ventilation and rodent infestations. Above ground, the manhole access points are often in the middle of busy streets requiring set-up of a cone zone to try and protect workers from passing traffic.

“You capture the data you need for one job and then have information someone else might need for another without a second site visit.“

This combination of hazards compels workers to spend as little time inside the manhole as possible. As a result, they have traditionally captured only the measurements they need for the project at hand – usually with a surveying level rod.

You capture the data you need for one job and then have information someone else might need for another without a second site visit. One of the most common applications is measuring the elevations of pipe inverts to map a water supply or drainage network in preparation for system expansion or maintenance. Personal hazards aside, making accurate asset measurements in a tight underground space with a long level rod can be challenging.

The ZEB Revo is increasingly being turned to for these jobs because the handheld laser scanner is fast, accurate, and captures comprehensive point clouds. Most importantly, it keeps personnel out of harm’s way. Favoured for manhole environments because of its high IP rating, which means it can be used in dirty and wet conditions, the ZEB Revo can be lowered into the underground space with the GeoSLAM Cradle.

In just a few minutes, the lightweight device can capture 360-degree scans inside the space regardless of available lighting. Even if the assets being surveyed are offset from the opening or several meters down tunnels, the ZEB Revo captures the 3D scan data needed to generate an accurate point cloud of the subsurface space.

“The first benefit of laser scanning [in manholes] is safety. The second is you collect a very comprehensive and complete data set. You capture the data you need for one job and then have information someone else [in the organization] might need for another…without a second site visit.

Industry

Engineering

Scan time

6 months

Location

Various,

Denmark

Size

400

buildings

Scanned

Municipal

buildings

COWI | Words by Morten Thoft

Digital technology is changing the way we design, construct and maintain our infrastructure. With the built environment ever more complex, traditional 2D data is not up to the task. As we move towards a more intelligent, more integrated, BIM-focused methodology, 3D data is becoming the norm. To stay ahead of the competition, surveying firms need to integrate innovative engineering approaches, digital technologies and intelligent data.

COWI is a multi-discipline engineering and planning firm based in Denmark. We have been eager to accelerate survey workflows and, as a result, have embraced digital engineering and added several GeoSLAM solutions to our arsenal of specialist scanning equipment. In just 6 short months since acquiring their first handheld laser scanner, a two-man team at COWI has used the ’go-anywhere’ mapping device to survey the interiors of some 400 municipal buildings; mapping over 16,000 rooms and measuring more than 300,000 m2 .

“We can now measure building plans 10-times faster than we used to with total station or traditional survey equipment.“

GeoSLAM’s solutions are changing the way we survey buildings. We can now measure building plans 10-times faster than we used to with Total Station or traditional survey equipment. Our decision to purchase another GeoSLAM solution was easy. With their handheld devices, we surveyed more buildings with more rooms in six months than traditional survey equipment would have allowed in many years. And we were able to capture more information in the process.

Builders by Design | Words by Nick Philips

Established in 2001, Builders by Design Ltd are a multi-disciplinary design and construction company based in London. Their expertise and services are mainly in the residential sector for new builds, conversions, and extensions. The core business is a combination of collaborations via competitive tender, negotiated contracts and design and build. They also have a bespoke joinery workshop facility in Park Royal, designing and fabricating furniture, kitchens, windows and doors. One of their greatest achievements to date, was being selected as the main contractor for Peacock House, a new build in Aldeburgh, Suffolk which was awarded a National and Regional RIBA award and was longlisted for Grand Designs House of the Year in 2017.

We spoke with Director, Nick Phillips, following their recent purchase of their GeoSLAM ZEB Revo RT to get an understanding of how this was helping to support their business. Previously, external companies were appointed to produce the 2D surveys which proved to be expensive, time consuming and not without errors and omissions.

Traditional 2D surveys instructed, would only take limited data, meaning important details on areas, such as staircases were incomplete. Inevitably there were times during the later stages of design and construction that the absence of such details required re-working of proposals. The manual process was also not very efficient, as it could take a full day for 1 person to survey a 3-bedroomed house and several weeks to receive the results. Nick identified that projects with existing structures should always start with comprehensive 3D data, which led to the purchase of the GeoSLAM ZEB Revo RT to enable 3D data capture in-house.

“Bringing 3D data capture in house was the obvious next step, with speed and accuracy important factors. For this and other reasons we selected GeoSLAM to provide the equipment and software required. It has had a positive impact on our workflows, which we will look to keep improving“

Before purchasing the ZEB Revo RT, other scanners were considered, such as terrestrial and static, but there were time and software limitations to adopting these more traditional systems. Using these methods was not efficient enough for Builders by Design, as they needed technology with speed, accuracy, and ease of use. Using GeoSLAM handheld solutions meant they could complete between 6-8 scans a day, with the accuracy they needed, whereas a static scanner may only achieve 1-2 scans a day. With current Covid-19 restrictions, having a single operative on site for only 30-minutes to complete the internal and external data capture can bring logistical advantages where a property is still occupied.

Builders by Design have integrated the ZEB Revo RT as an integral part of their digital workflows, providing all the stakeholders with dynamic visualisation material for project design. They use the ZEB Revo RT to scan the 3D point cloud, importing the data into CAD software to create 3D models and 2D planning documentation for the design team. Working in 3D environments together with other visualisation tools has also created a transparency and understanding of design intent between the Architect, the site team and the client that could not have been achieved with 2D plans, sections, and elevations.

Having utilised the GeoSLAM ZEB Revo RT in-house to identify the many benefits to the business, they plan to collaborate with external Architectural and Design practices undertaking their own digital transformation journey, to build templated 2D documentation of existing buildings, 360° site photos, 3D model and bespoke CAD packages. In closing, Nick emphasised that:

“Delivering a point of difference from the competition will become increasingly essential to remain relevant in the market, requiring new 3D technology adoption to assist in achieving fewer errors and more predictable outcomes for all building projects.“

Industry

Civil

Engineering

Scan time

4.5 hours

Location

Kansas City,

USA

Size

42,592 sq/ft

Scanned

School

BHC Rhodes | Engineering company

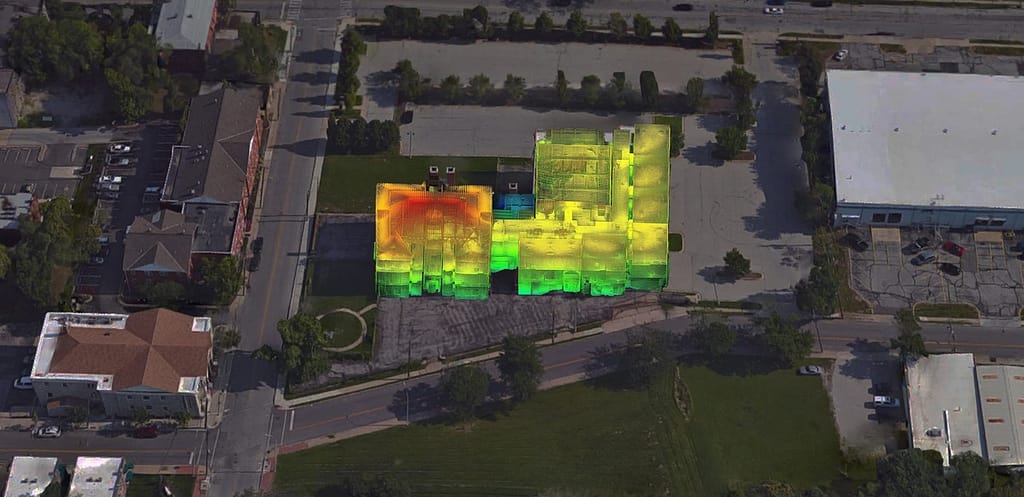

Transforming an aging school in the Jazz District of Kansas City to a community arts centre required the power of today’s real-time technology.

The Attucks building, built in 1905 and renovated in 1922 due to overcrowding, has undergone several developments over the years. For any plans to be approved on the site of the Attucks School, the commission needed substantial and comprehensive drawings – materials, floor plans, site drawings and elevations.

“A BIM model was provided two weeks earlier than expected, providing a comprehensive picture of the asset“

With several hazards identified – visible deterioration in the wood floorings, ceiling collapses, and air quality conditions including asbestos – a fast, accurate and safe survey technique was required.

Civil engineering firm, BHC Rhodes, embarked upon the complex task of a 3D Revit BIM (Building Information Model) using GeoSLAM technology. The handheld “go-anywhere” ZEB Revo is designed to be used without comprehensive training, meaning you can ‘pick up and go’, saving additional preparation time for any members of staff previously unfamiliar with the technology. It’s a simple setup and data gathering is quick and easy; wherever you can walk, you can scan.

With the aid of these lightweight, mobile scanners, specifically designed to scan difficult to access spaces, the entire property was scanned in only 4.5 hours, recording more than 43,000 measurements per second. A BIM model was provided two weeks earlier than expected providing a comprehensive picture of the asset. Only with these modern tools could a real-time digital twin of the ageing building be created quickly, and safely – saving considerable time and money.

Why firms need to double down

Innovation in construction gets a bad rap. Which feels somewhat unfair, after all, it is a ‘bricks and mortar’ industry, heavily reliant on equipment, machinery and a ‘hands-on’ workforce. The industry is often flouted as falling behind others in how it has embraced technology. Yet in recent years in particular, many forward-looking construction companies have deployed innovative solutions to better, and more safely, construct buildings.

But few companies have captured the full benefit of digital, and some have questioned whether they have the right approach. Piloting is one-thing, getting company-wide adoption is another. And it’s not hard to see why. As construction projects are typically fragmented, there are a number of hurdles for companies to overcome:

According to the Future of Construction, Building Information Modelling (BIM) is the centre piece of the construction industry’s digital transformation. Over the last decade BIM awareness and adoption has grown from little more than 10% in 2011 to over 70% in 2020. And the benefits speak for themselves: NBS reports that adopters report greater predictability of building performance, price and programme; as well as reduced risk and increased profitability.

Yet while BIM standards are becoming embedded, and thankfully fewer people see BIM simply as ‘3D modelling’, there is still work to narrow the gulf between ‘BIM engaged’ and ‘BIM laggards’. Deploying cutting-edge technology is only one aspect. Having the mindset and approach to collaborate is what will really unlock the value of the tech.

At the core of BIM success is collaboration. In fact, you can’t really ‘do’ BIM if you don’t have the entire team on board in the earliest stages.

NBS

Aside from BIM, there are a number of connected construction technologies that are being adopted to streamline and ease the process of constructing our built world. But given the array of new technologies on offer, where’s the best place to start?

When the pandemic hit in 2020, and ‘working from home’ just became ‘working’, we all realised the difficulties in communicating and collaborating with remote teams. Add to that the challenge construction professionals already had of multi-layered teams, and it’s easy to see where the friction could be.

What makes construction complex is not the complexity of the building, it’s the number of people that are required to work together to make it happen.

Nathan Wood, Executive Director, Construction Progress Coalition

While it’s tempting to cherry-pick solutions that fix a particular problem, developing narrow use cases may mean missing out on the wider opportunity. But by taking a collaboration-first approach and starting with technology that improves knowledge-sharing, smooths interactions and boosts interoperability, this could have significant knock-on effects to address other challenges, too.

For example, selecting tech that has the potential to integrate well with all other platforms means you’re not facing digital isolation. And by putting data transparency and data collection first by choosing tools that create 3D maps, this data can in turn, be used as the anchor for better decisions between all parties. And in unlocking collaboration barriers, this could be the key to creating lasting value.

In ‘Decoding Digital Transformation in Construction’ McKinsey & Co., cites how one collaboration tool drove down rework costs for a leading contractor. The quoted example talks about the contractor’s process for collecting comments on defects found onsite. Workers typically provided anecdotal, unstructured or difficult to act on feedback, which resulted in unplanned rework and delays.

This radically turned around when the contractor introduced a digital app to tag defects against specific elements in the BIM model and store them in a common data environment. A simple but effective collaboration solution that on-site teams could easily adopt. It smoothed out communication plus reduced rework and improved the bottom line.

Companies that take a collaboration-first approach put themselves in a much stronger competitive position. Not only can they get first-mover advantage, but they can boost productivity at the same time as keeping costs down:

Construction has a long record of poor productivity and firms experience delays on a quarter of their projects, with nearly one fifth of projects going over budget. But with the wide adoption of mass data collection technologies, site workers can now carry out a weekly, or even daily, ‘as-built’ scan of a site which highlights any discrepancies or defects during the build. NBS research suggests that 3D modelling technology can deliver cost efficiencies (60%) and increase speed of delivery (55%).

With multiple stakeholders engaged at various points of the project lifecycle, having “one source of the truth” such as BIM, enables greater collaboration and more informed decision-making. Data is brought out of silos and there’s a consolidated view of all critical information, that everyone can see, in real-time. This improves workflow, predictability and removes bottlenecks. Critical to this is having a mapping tool that accurately captures the data in 3D model form and provides an anchor for all data extracts.

AI-powered solutions not only automate but accelerate non-value-add tasks across teams. This helps improve site efficiency and allows site workers to expand their capabilities. For example, on site, AI can provide real-time alerts in the event of safety violations, such as if PPE is not used at all times. And in the back office AI can easily reconcile budgets and billing by matching what happens on the ground to what’s been billed.

To be able to make better decisions faster, construction professionals need to know they’re confidently working with the most accurate data. A Common Data Exchange, such as the one being trailblazed by the Construction Progress Coalition will not only transform project collaboration but address the common data dilemma of getting the right info to the right people at the right time. It will also improve overall data integrity, data usage and make it easier to evidence compliance.

Being able to create an exact mirror of the asset in a digital twin, means you can spot and correct irregularities before building work starts, as well as monitor and correct defects on-site. This enables clients to mitigate some of the risk, time and cost impacts of complex construction projects. IDC predicts that companies that invest in digital twin technology improve cycle times of critical processes by 30%.

Royal BAM Group has a phrase that has become synonymous with the company which is, ‘We make it before we make it’. This digital-first approach enables the company to easily visualise the construction schedule, flag any potential problems and get back on track – while saving on rework.

This type of approach which aims to manage and share data between all key parties, is especially helpful when regenerating buildings or constructing new builds in busy cities. Aside from operating on constrained sites in busy locations (e.g., where the site footprint is the building footprint), sites are often live environments, with businesses in occupation. Staging construction offsite, or ‘just-in-time’ construction enables all stakeholders to virtually test the stress factors and tolerances of an asset in multiple ways, before the asset is built.

Wilmott Dixon is a privately-owned construction and interior fit-out specialist renowned for working on large and complex projects across the UK. To keep projects on-track, the contractor wanted to equip on-site teams with user-friendly mapping technology that could be quickly adopted and used by anyone. Scanners needed to be mobile, lightweight, and fast – and work in any weather. Mapping software needed to be automated, accurate and easy to interpret. GeoSLAM’s Construction Progress solution ticked all the boxes.

This innovative solution combines hardware, advanced SLAM and automated analytics for smart progress tracking. Site workers ‘walk-and-scan’ with a handheld SLAM scanner, and by simply plugging the scanner into a computer, the data is automatically processed using GeoSLAM’s smart data platform, Connect. This is digitally compared against the 3D model on record, and within minutes an automated report will show you the percentage of work complete/incomplete and a simple visualisation of the site, highlighting 3D changes.

The data is centrally stored providing a clear and reliable audit trail and remote teams can confidently share progress updates knowing they have a central source of the truth. Teams can continuously collect data as often as they need to, in some cases several times a day. The automated solution not only saves time and money but enables Wilmott Dixon to be on the front foot and proactively address any issues. It’s just one way the national contractor delivers lasting value.

Like many industries, the future of construction is firmly rooted in leveraging the benefits of digital technology to deliver better outcomes. While building sites will always be an organised chaos of physical, tangible assets, there’s still a huge opportunity for technology to transform the way buildings are constructed. But if you’re not getting the full value from digital technology alone, don’t give up. There is a better way.

Given the history of fragmentation and siloed working in construction, it follows that any, and every, digital innovation should seek to address this traditional way of working. And in doing so, will not only be a single-use case, but will have ripple effects across the whole value chain. Now really is the time to double down on digital efforts, collaboratively, of course.