Proper planning was essential as demolition can be potentially hazardous for the safety of personnel due to the plant’s age-structure, and onsite teams often having to operate across split levels, in total darkness. The removal of contaminated waste can be equally challenging. Cost is also a major factor and companies responsible for shutting down plant are continuously looking at ways to be cost effective while providing a reliable, fast and efficient service.

Aurecon, a global engineering, design and advisory company, won the tender from the City of Cape Town to project manage the site for the final stage of decommission. This involved surveying the plant whilst stripping, clearing and removing unused material, redundant equipment and certain historical structures. Their task also included securing all remaining structures, leaving the site in a secure state and registering servitudes for remaining bulk services. Aurecon found Athlone to be a challenging project due to accessibility issues and lack of light. Also, because of the Power Station’s historical importance, salvaging certain unique equipment had to be considered. The team needed a simple and effective solution that could accurately map the site quickly while keeping them safe in a tough environment.

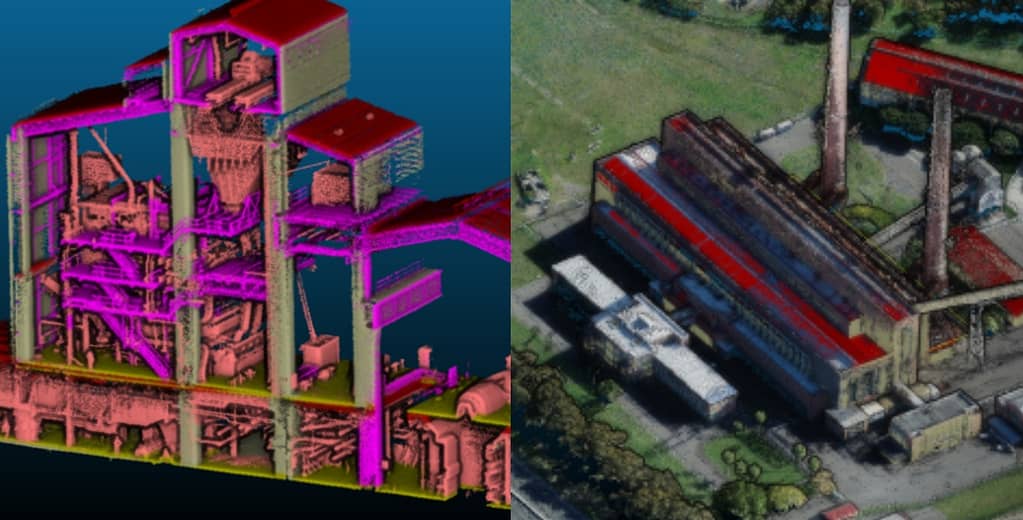

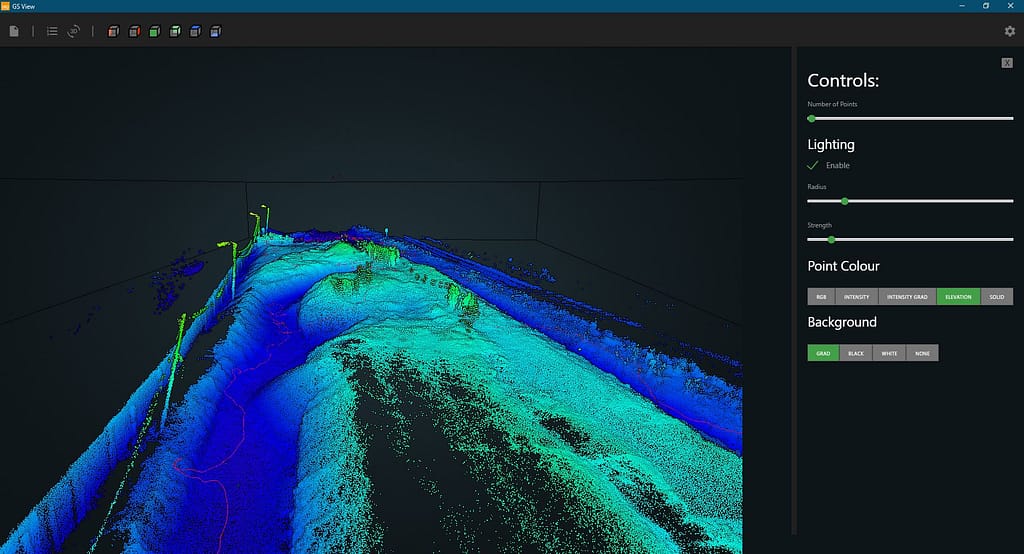

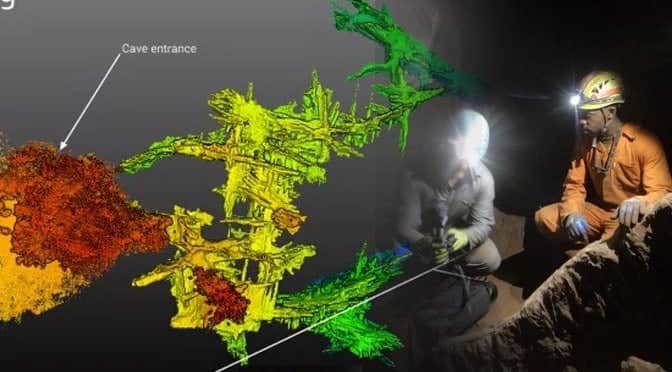

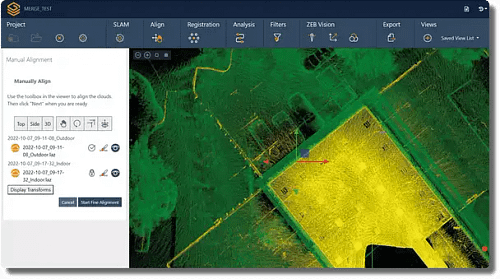

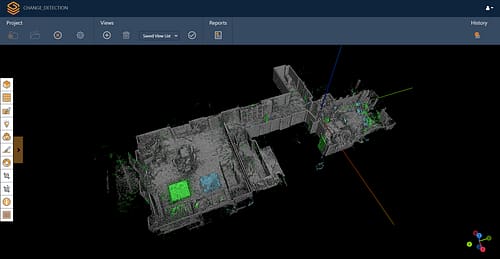

Aurecon chose to work with mobile LiDAR scanners so that the historians, structural engineers and environmentalists could have the data they needed, without having to enter the potentially dangerous site. For the Athlone project, GeoSLAM’s ZEB Revo RT scanner and ZEB Pano camera were used, as well as the ZEB Horizon and ZEB Cam. The building’s interior and exterior were scanned with the ZEB scanners The two data sets were merged to provide a full 3D point cloud of the entire building.

Using the Pano, the team generated photos that were incorporated inside the point cloud, so that the offsite survey team could have greater visualisation of the site to feedback commentary. The efficiency of the scanners and speed of capture meant that unlike other scanning methods, the team could repeatedly capture the site. This meant that decisions and assessments could be taken frequently, without the need for lots of people to visit the dangerous site.

In total, the whole facility was scanned in three days with data sets processed overnight, a total of eight hours. The combined datasets were available within a week, which enabled Aurecon’s modellers to commence work on the classification of components in the power station.

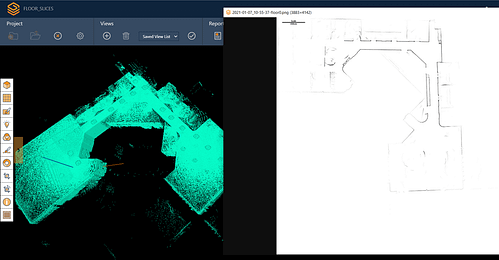

The final 3D point cloud representation of the interior of the power station enabled the engineering team to assess and quantify the amount of salvage and scrapped material to be removed from the site, and to plan the logistics of the removal in context with the physical shape and size of the existing building.

The accurate 3D model equipped the stakeholders with information that allowed them to safely and precisely analyse for activities such as material quantification, condition assessment and the preparation of decommissioning method statements.