The role of LiDAR plays in convergence analysis

Last Updated on 11th May 2023 The role LiDAR plays in convergence… Read More »The role of LiDAR plays in convergence analysis

Last Updated on 11th May 2023 The role LiDAR plays in convergence… Read More »The role of LiDAR plays in convergence analysis

Last Updated on 30th March 2023 What part does LiDAR play in… Read More »What part does LiDAR play in the Disaster Management Cycle ?

Kansas,

USA

Approx. 20 minutes per scan

Over 1 million sq/ft per year

Buildings and Underground Oil Tanks

Surveying

The Kansas Adjutant General’s Department coordinates resources for local, state, and federal use. They also develop internal use documents for the military, including surveying building interiors to create up-to-date and accurate floorplans for military members within Kansas.

They have about 35 sites throughout the state, with some locations 100s of miles away from the headquarters. Further, the Adjutant General’s Department manages approximately 250 buildings state-wide, totaling around 2 million sq. ft. of interior space. These factors have led to some difficulties in keeping up with projects, and any changes to the buildings and layouts.

The team found that when remodelling buildings, they were having issues getting as-builts completed in time. As-builts are documents that are used to compare a building’s design plan versus its final measurements. They also provide accurate blueprints of the building, and the surrounding land, as actually constructed at the end of the project.

Being able to have one person go out to capture all of the data and have the most current floorplans, along with the accuracy of the scanners is a gamechanger

To tackle these issues, the team decided to adopt LiDAR laser scanning technology to aid them in their projects and found GeoSLAM’s ZEB Revo to be the best option. By acquiring GeoSLAM’s technology, the Kansas Adjutant General’s Departments’ goal was to scan over half of their 2 million sq. ft. of interior space every year.

The ZEB Revo is handheld, accurate and fast, providing the team with a perfect tool. In addition, the simplicity and ease of use means only one team member needs to travel to a site, when necessary. Previous methods of data capture were not as quick or accurate. The ZEB Revo data capture leads to a faster return on projects, higher levels of accuracy, and a high return on investment.

By using the ZEB Revo, the Kansas Adjutant General’s Department have updated over 1 million sq. ft. of interior space, achieving their overall goal, with just one technician visiting half of the sites per year. The speed of capture of the ZEB means that the average time it takes the team to carry out a scan is just 20 minutes. By collecting accurate measurements, they can now regularly update their GIS database, which provides up to date floorplans throughout the state.

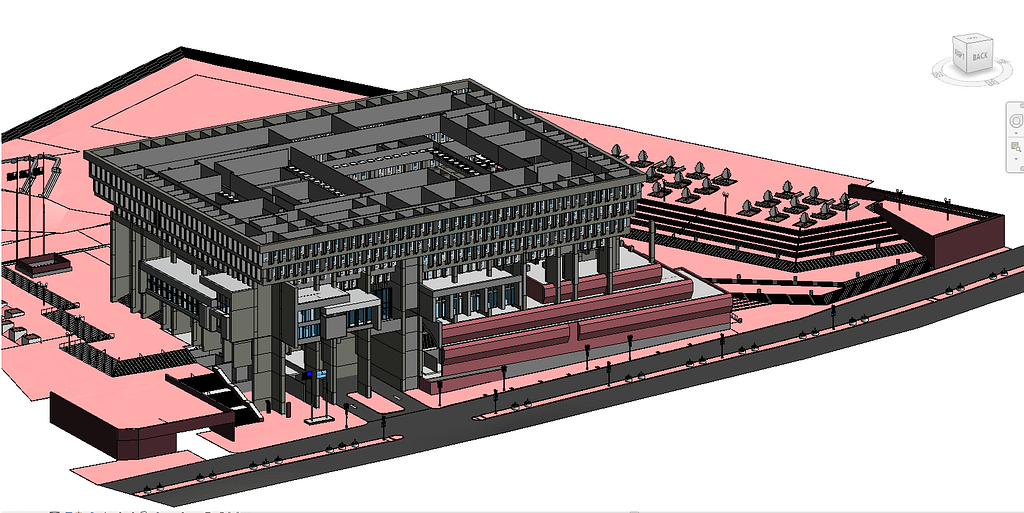

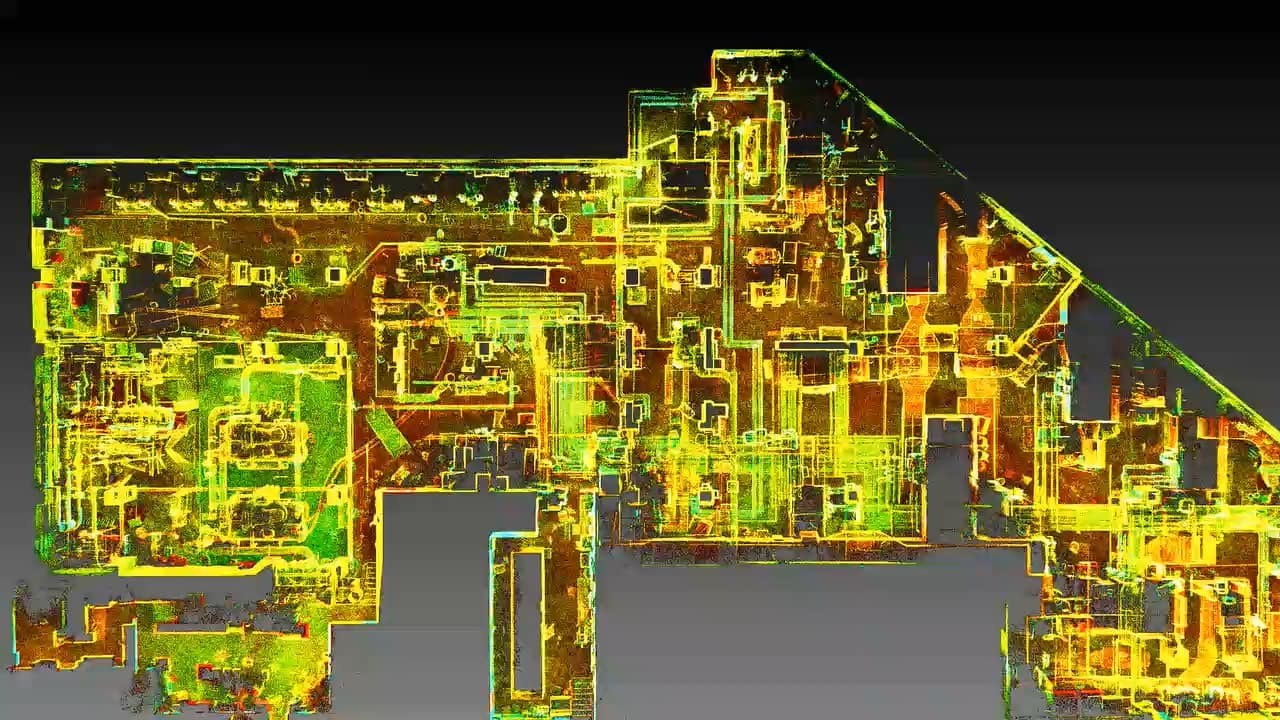

Data from the ZEB Revo is also used to create ‘X-Ray’ views of their properties for future plans and layouts.

Recently, they have expanded their use of handheld LiDAR technology by acquiring a ZEB Horizon, which they use for a variety of reasons. The increased range and data capture points make the ZEB Horizon a great option for large exterior scanning. This is important to the Adjutant General’s Department as they cover land of up to 50 acres.

The Kansas Adjutant General’s Department also have tanks that contain hazardous material which they need to track carefully. Using the ZEB Horizon, they scan exterior environmental factors to figure out contour lines within their complex. This helps them work out where any spillages of hazardous material would be, should one occur.

With the ZEB Horizon, the team also carry out exterior scans for asset management. Due to the scanners ease-of-use, one engineer can attach it to a truck and drive around their complex. This enables Kansas Adjutant General’s Department to scan their entire site and keep on top of their buildings and resources.

The team are also looking to expand this by attaching the ZEB Horizon to a UAV in the future.

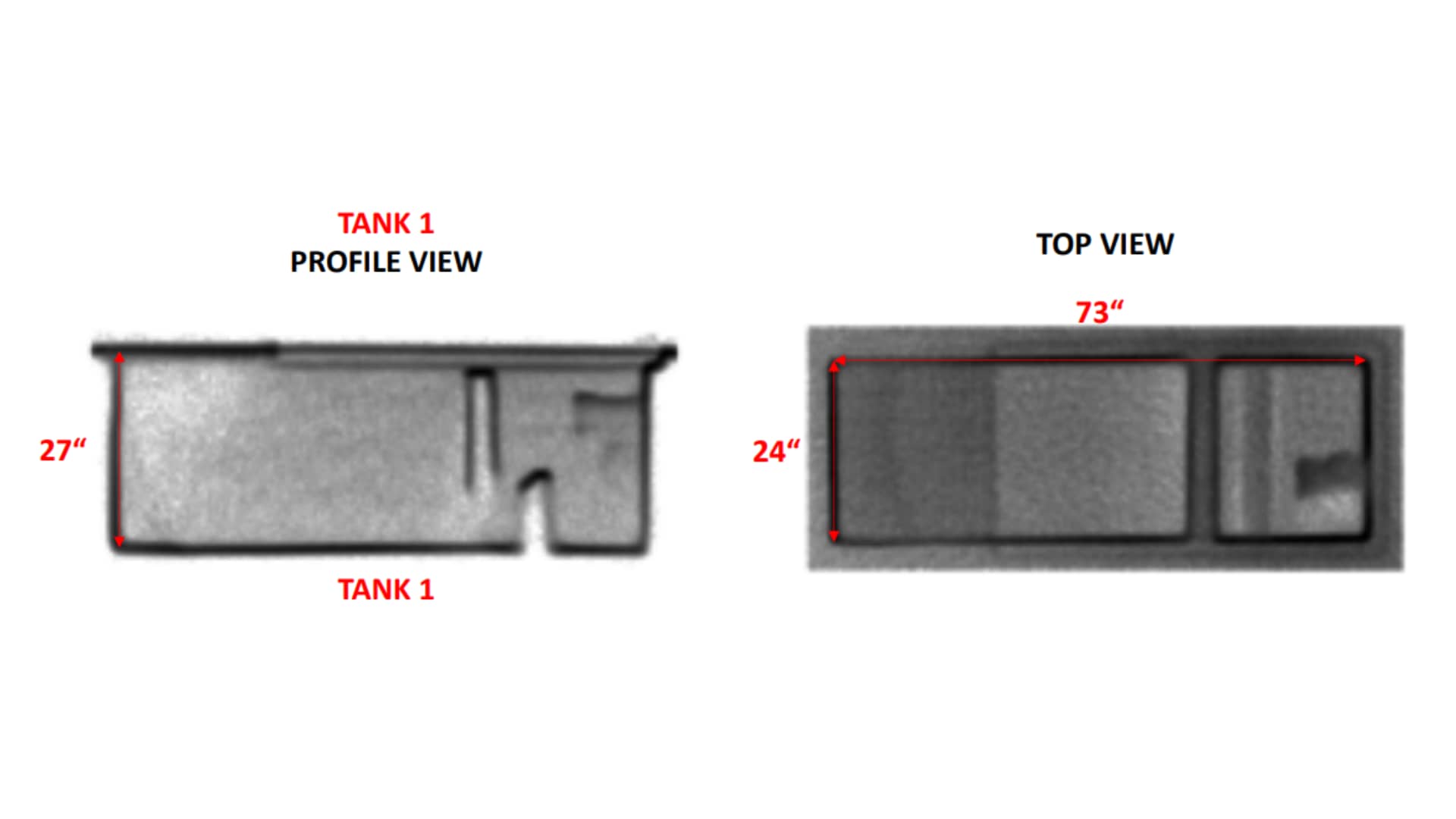

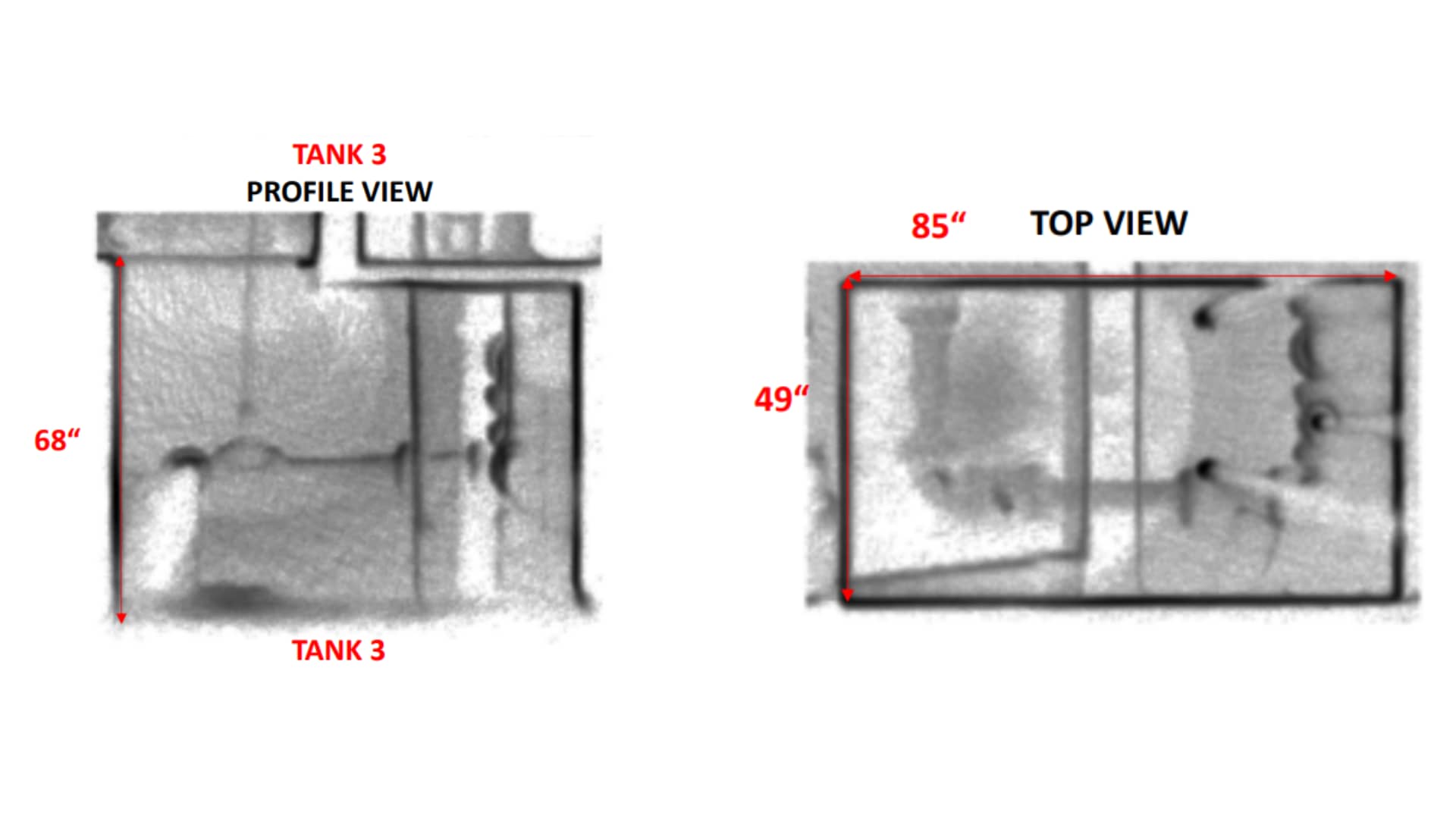

The ZEB Horizon’s time saving, and accurate scans have proven to be a cost-effective method of data capture. For example, scans of underground empty oil storage tanks showed that the Kansas Adjutant General’s Department had been over estimating the tanks collection capacity, leading to an adjustment of the servicing contract.

Since The Kansas Adjutant General’s Department acquired GeoSLAM’s technology four years ago, they have carried out approximately 2000 scans, and this number continues to rise.

Further, the contractors and architects that create as-builts are now using The Kansas Adjutant General’s Department to quality check their work for accuracy. Using GeoSLAM laser scanners, they help find errors in specifications and relay that information to the contractors.

With the help of Seiler Geospatial Division, Kansas Adjutant General’s Department have been able to significantly improve their workflow. To find out more about Seiler, click here.

If you’d like to learn more about how GeoSLAM solutions can help you, submit the form below.

Real Estate is a fast-moving and highly competitive market. Companies are reliant on good customer relationships based on trust. They realise the importance of providing accurate measurements and specifications of the properties they are advertising. Buildings incorrectly measured could be under or overvalued, which could result in complaints, invalidate a sale, or damage their reputation.

This is particularly pertinent in the Netherlands, as they have placed a high level of importance on delivering accurate floorplans when advertising a property. In fact, a new regulation was introduced in 2010 after properties in Amsterdam were sold at a higher cost, after being overvalued due to incorrect floorplan measurements. The regulation, BBMI, requires businesses advertising properties to provide accurate floorplans or face potentially heavy fines.

This required businesses to think differently about how they could quickly and accurately assess the properties they were advertising.

Rotterdam based media and marketing company, ZIEN24, realised they needed to modernise how they measure properties in light of the regulations. ZIEN24 produces content and digital floorplans for estate agents, covering all types of residential and commercial properties.

The company began measuring properties using laser rangefinders, which were not only time-consuming but also not cost-effective. The company received complaints when properties were not measured within the limits of the regulation, and the team had to occasionally return to properties to re-measure them. In addition, ZIEN24 was sending both photographers and surveyors to properties, which was not cost-effective or ideal for their clients.

Having worked with point clouds previously, ZIEN24s co-owner, Boy Van Houten, thought that they could be the solution for accuracy. However, they needed a setup that was quick and effective, so static-based systems were not an option. After researching different scanner options, they decided to try GeoSLAM’s ZEB Revo RT with the ZEB Pano accessory.

The ZEB Revo RT is highly accurate, fast, and easy to use. As it requires minimal training, ZIEN24 taught their photographers to scan properties when they’re on location taking marketing photos. This negated the need for a surveyor, saving ZIEN24 money which could be passed on to their clients. The scanners accuracy largely removes the risk of human error, and ZIEN24 have not received any complaints since starting to use GeoSLAM scanners back in 2019.

The addition of the ZEB Pano allows them to take informative 360 degree panoramic photography, at a much quicker pace, during a scan. The ZEB Pano stores the exact location of each panoramic image within the scan, enabling more accurate and less intrusive property surveys. This is vital for ZIEN24, as the popularity of virtual house tours increases within the real estate industry.

The GeoSLAM scanner not only gives us confidence in the end product but gives our clients peace of mind knowing that our fully-automated measurements are highly accurate.

As the scanner captures in real-time, the photographers can easily ensure that they are capturing every room, as they walk around. Furthermore, the speed of capture, 200m2 in 15 minutes, means that more properties can be assigned to photographers per day. The data is then processed in their offices in China, and accurate floorplan reports are typically turned around within 24 hours.

The ZEB Revo RT has also helped them to expand into other markets, and they now offer scanning services to support BIM models.

If you’d like to learn more about how GeoSLAM solutions can help you, submit the form below.

Surveying buildings is difficult and accessing hard to reach areas, like dropped ceiling or raised floors, without disrupting business can be seemingly impossible. In this blog we’ll discuss how SLAM and LiDAR technology has made scanning behind dropped ceilings a simple process.

Location: United Kingdom

ZEB Scanner: ZEB Revo RT

This data was captured using GeoSLAM’s ZEB Cradle accessory.

Would you like to see a specific dataset that’s not on this page? Contact [email protected]

Mapping an Iconic Landmark

Boston City Hall was built in 1968, to help boost the city’s economy after years of stagnation. The building and surrounding plaza sought to modernize the city’s urban centre, reinvigorating the run-down neighbourhood of Scollay Square.

Despite the public investment project being welcomed by the people of Boston, the buildings ‘brutalist’ style of architecture created debate amongst the locals, with some suggesting you either love or hate the concrete design. In spite of the concerns from the public, the city

hall has been home to the mayor of Boston and the city council for over 5 decades, and the ‘brutal’ style of architecture has become part of Boston’s rich history.

To encourage more people to use Boston City Hall and to increase accessibility, it was decided in 2017 that the City Hall would be renovated to serve a more modernized purpose. The infrastructure upgrades include better access to utilities, plants and fountains in the plaza area, with the intention of encouraging more people to visit.

The Horizon was a gamechanger…it’s just amazing in terms of the scanning distance, power of the sensor and the ability to easily capture the entire plaza.

Peter Garran and his team, from Aerial Genomics, were appointed by The City of Boston and Sasaki with the task of scanning both the interior and exterior of the City Hall, in anticipation of the renovation project. Spanning 9 floors and housing multiple individual rooms, as well as a busy plaza area, the task of mapping the building threatened to take several months to complete. Also, the City Hall is an active office that contains confidential rooms and Aerial Genomics did not want to disrupt everyday operations too much. Considering their options, the team decided the fastest and most cost-effective way of mapping the building and its surrounding area would be to use mobile LiDAR scanners.

They chose a ZEB Horizon to scan the exterior and inside the Main Hall. The ZEB Revo RT was used to map the buildings vast interior. These scanners were chosen due to their speed, accuracy and mobility. By simply walking around the building, Peter and his team captured the large layout, saving them time.

As they were scanning during the pandemic, it was key for Peter and his team to spend as little time as possible in the building and compared to other scanning methods, GeoSLAM’s scanners were able to deliver on that goal. With the ZEB Horizon, Aerial Genomics captured both the exterior and interior of the Main Hall in just 4 scans, and in less than 2 hours. This scanner was specifically chosen to scan the Main Hall due to its 100m range being able to capture the high walls. To help combat getting in the way of the City Halls’ day-to-day business, the team were given limited amounts of time in the evening to scan a multitude of rooms inside the Hall. Using the ZEB Revo RT, the team could scan the almost 1 million square feet interior, in just 4 nights, consisting of 5 hours each night.

The scans were processed using GeoSLAM Hub and merged to create one point cloud, by Aerial Genomics. The manoeuvrability, ease of use and accuracy that the ZEB scanners provided meant the data collected was ready within a week, to be created as a BIM model to send to the architects. The simple, easy to use solution meant the architects could start thinking about the redevelopment and renovation, without the need to visit the hall during a pandemic. The final BIM model, created in Autodesk Revit, is still referred to today.

If you’d like to learn more about how GeoSLAM solutions can help you, submit the form below.

All over the globe, countries are looking to nuclear and hydro renewables, not only to provide their electricity needs but to meet climate goals. This is resulting in the shutting down of coal-fossil power plants that no longer have a role to play in a fast-changing world.

Opened in 1962, the Athlone Power Station was the last coal-fired power station operating in Cape Town, South Africa when it stopped generating power in 2003. The iconic cooling towers, which were known by locals as “The two ladies of Athlone” and had long been a feature of the Cape Town landscape, were demolished several years later.

The efficient user-friendly GeoSLAM equipment enabled the team to safely and comprehensively survey this hazardous and complex plant.

Proper planning was essential as demolition can be potentially hazardous for the safety of personnel due to the plant’s age-structure, and onsite teams often having to operate across split levels, in total darkness. The removal of contaminated waste can be equally challenging. Cost is also a major factor and companies responsible for shutting down plant are continuously looking at ways to be cost effective while providing a reliable, fast and efficient service.

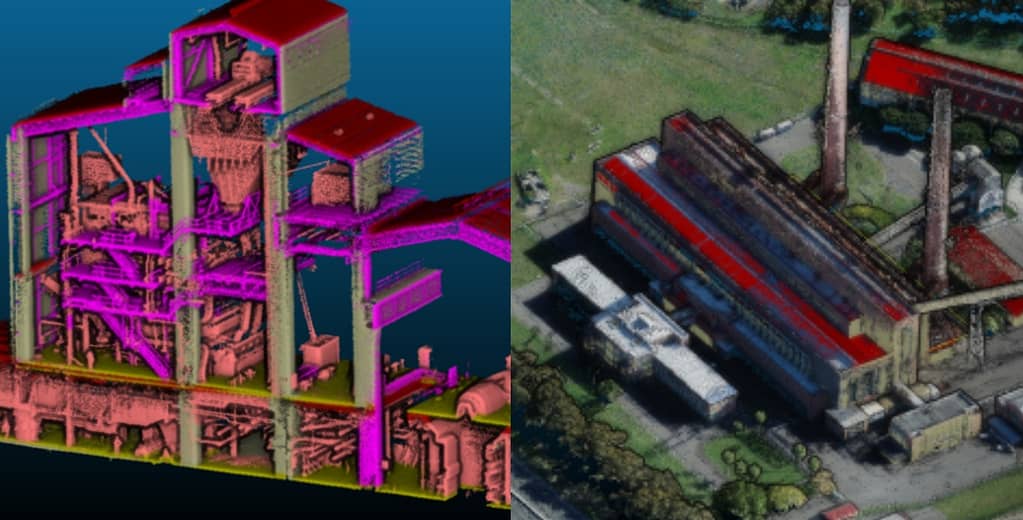

Aurecon, a global engineering, design and advisory company, won the tender from the City of Cape Town to project manage the site for the final stage of decommission. This involved surveying the plant whilst stripping, clearing and removing unused material, redundant equipment and certain historical structures. Their task also included securing all remaining structures, leaving the site in a secure state and registering servitudes for remaining bulk services. Aurecon found Athlone to be a challenging project due to accessibility issues and lack of light. Also, because of the Power Station’s historical importance, salvaging certain unique equipment had to be considered. The team needed a simple and effective solution that could accurately map the site quickly while keeping them safe in a tough environment.

Aurecon chose to work with mobile LiDAR scanners so that the historians, structural engineers and environmentalists could have the data they needed, without having to enter the potentially dangerous site. For the Athlone project, GeoSLAM’s ZEB Revo RT scanner and ZEB Pano camera were used, as well as the ZEB Horizon and ZEB Cam. The building’s interior and exterior were scanned with the ZEB scanners The two data sets were merged to provide a full 3D point cloud of the entire building.

Using the Pano, the team generated photos that were incorporated inside the point cloud, so that the offsite survey team could have greater visualisation of the site to feedback commentary. The efficiency of the scanners and speed of capture meant that unlike other scanning methods, the team could repeatedly capture the site. This meant that decisions and assessments could be taken frequently, without the need for lots of people to visit the dangerous site.

In total, the whole facility was scanned in three days with data sets processed overnight, a total of eight hours. The combined datasets were available within a week, which enabled Aurecon’s modellers to commence work on the classification of components in the power station.

The final 3D point cloud representation of the interior of the power station enabled the engineering team to assess and quantify the amount of salvage and scrapped material to be removed from the site, and to plan the logistics of the removal in context with the physical shape and size of the existing building.

The accurate 3D model equipped the stakeholders with information that allowed them to safely and precisely analyse for activities such as material quantification, condition assessment and the preparation of decommissioning method statements.

If you’d like to learn more about how GeoSLAM solutions can help you, submit the form below.

ZEB Revo RT | Housing and Building National Research Centre

The government of Egypt (GoE) are leading several initiatives to reuse and recycle the ever-increasing quantities of construction and demolition Waste (CDW) around the country. These initiatives include a national strategy and action plan to effectively manage around 40 million tons of CDW generated annually. They target to recycle 50% of CDW materials by 2030. One of the major challenges facing Municipalities in Egypt is calculating the amount of CDW accumulated, due to illegal dumping of waste being common place in cities.

Commissioned by the Ministry of Environment and the GIZ institution, HBRC (Housing and Building National Research Centre) have been tasked with finding effective methods for quantifying and characterising the amount of CDW in four Egyptian Governorates (Gharbia, Kafr-El-Sheikh, Assuit and Qena).

This project paves the way to developing an optimal construction and demolition waste management strategy in Egypt. The research team used GeoSLAM’s ZEB Revo RT SLAM laser scanner to map the construction waste piles. The scan data is a sound method for quantifying waste volumes over a period of time, due to the ease of capture and accurate data.

The traditional surveying of CDW accumulations was not practical as CDW locations are difficult to walk through and experience rapid changes to the waste quantities.

The ZEB Revo RT is ideal for rapid data capture in real time, making it the perfect tool for this job. By walking through the construction and demolition waste sites, the team are mapping as they go, shortening the amount of time spent in a hazardous environment, reducing health and safety risks.

The simplicity of the solution means that anybody can capture the data, with minimal training, making the scans repeatable as often as needed. Covering an area of 84,823 m2, the research team conducted 12 scans, dividing the route into zones and each scan lasted an average of 17 minutes.

Once the scanning was complete, they opened the data in GeoSLAM Hub where the point cloud can be viewed and prepared for GeoSLAM Volumes. Using GeoSLAM Volumes, the researchers could accurately calculate the quantity of construction and demolition waste. The findings were reported back in a presentation during the third International conference on Smart Cities.

This way of calculating volumes is fast, efficient, cost effective, safer than other methods and repeatable, making the SLAM scanner the right tool for the job. The research effort opens the door into the utilisation of 3D modelling of construction waste management sites.

The application of laser technology would enable the quick and accurate estimation and modeling of waste quantities.

If you’d like to learn more about how GeoSLAM solutions can help you, submit the form below.

With increasing awareness of LiDAR technology, its applications are becoming more diverse. From helping to prevent natural disasters to mapping historic caves and restoring architectural wonders, our ZEB laser scanners have been involved in a range of interesting projects over the past 12 months.

Control points are points within a given area that have known coordinates. They are a key tool in the geospatial industry and can be utilised in a variety of ways, including georeferencing point clouds and aligning aerial images to terrestrial data. By using control points, surveyors are able to accurately map larger areas and position overlapping surveys of an area together. They can also be used in non-geospatial industries, such as construction and mining, to show clear temporal comparisons between multiple surveys of the same area. This method of georeferencing is also referred to as adjust to control.

Previously, checkerboards and spherical targets have been used as control markers – these items are captured in surveys and can be identified for georeferencing or aligning. The main drawback with these methods is that they rely heavily on human interpretation when processing, meaning that the processed datasets may be susceptible to an increased amount of error.

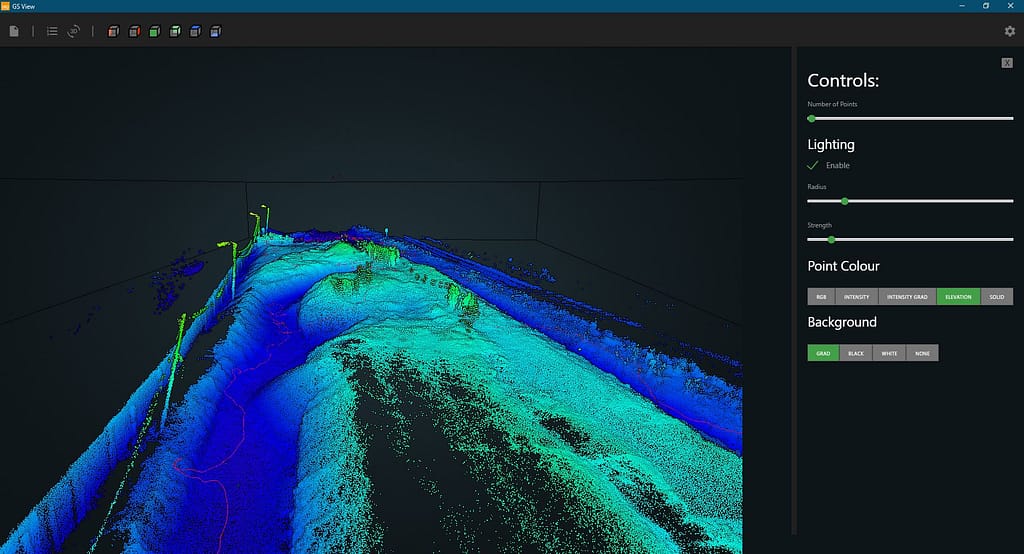

When capturing handheld surveys, GeoSLAM systems are able to collect reference points. These can then be matched with known control points to reference scans and increase the level of accuracy.

Easily reference point clouds and produce reports highlighting accuracy values.

Regularly monitor site operations (e.g. stockpiles) and hazards.

Compare changes over time and map progress onto predetermined CAD/BIM models.

Once georeferenced using control points, point clouds can be optimised further using leading third party software:

For more information about our third party partnerships, head to our integrations page.

Keep up to date with the latest news and thought leadership from GeoSLAM.

With increasing awareness of LiDAR technology, its applications are becoming more diverse….

Popular Nottingham bar as you’ve never seen it before A historic chapel,…

Using 3D laser scanning to map difficult environments The advances in handheld…

In this blog I am going to talk about the various locations we visited, and show the data we captured from historic locations around the country.